When choosing between advanced filter wheels and drawers, consider hidden costs like frequent replacements, maintenance, and compatibility issues. Advanced wheels may seem more efficient but can incur higher expenses if they wear out quickly or aren’t compatible with your current system, leading to costly upgrades. Proper maintenance and compatibility checks can help you avoid these pitfalls. Stay tuned to discover more ways to manage these hidden expenses effectively.

Key Takeaways

- Advanced filter wheels may have higher upfront costs but offer longer durability, reducing replacement expenses over time.

- Compatibility issues between filter wheels and existing control systems can lead to costly software upgrades or replacements.

- Poor physical design or size incompatibilities can increase installation costs and limit future upgrade options.

- Neglecting regular maintenance of filter wheels can cause wear-related failures, resulting in unexpected repair expenses.

- Investing in high-quality, compatible filter wheels and planning for physical constraints helps avoid hidden costs and prolongs system lifespan.

Hidden Maintenance and Replacement Expenses

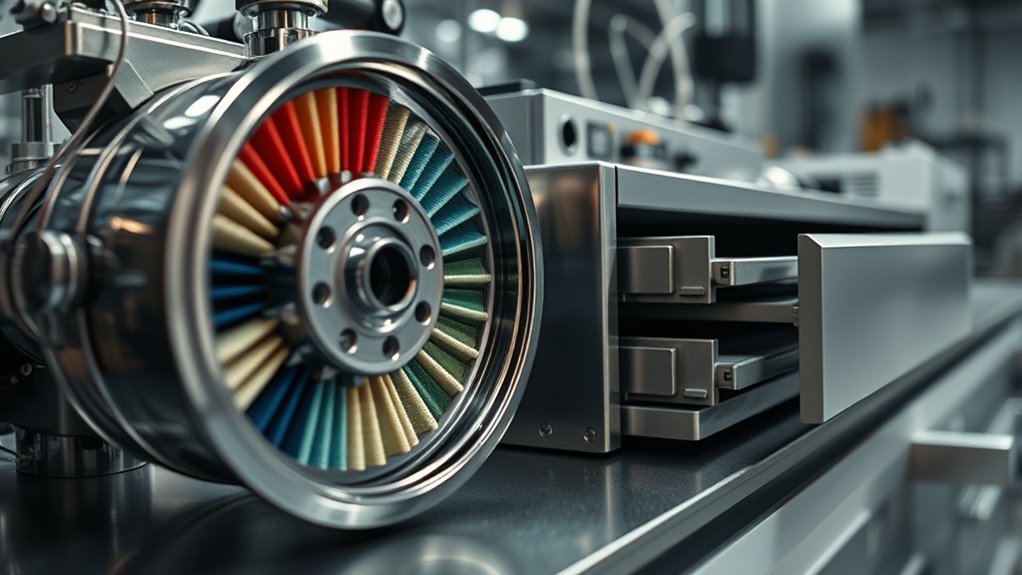

While filter wheels may seem straightforward, they often hide significant maintenance and replacement costs. The durability of a filter wheel directly impacts how often you need to replace it, which can escalate expenses over time. Poor durability means higher replacement frequency, leading to frequent downtime and increased costs for parts and labor. Additionally, worn or damaged filter wheels can cause misalignments, affecting image quality and requiring repairs. Over time, neglecting these issues can lead to more extensive equipment failures. To keep costs manageable, you should regularly inspect your filter wheels for wear and consider investing in higher-quality models designed for longevity. This proactive approach reduces unexpected expenses and ensures smoother operation, saving you money in the long run. Recognizing the importance of equipment maintenance can further help prevent unforeseen costs and extend the lifespan of your equipment.

Compatibility and Upgrade Challenges

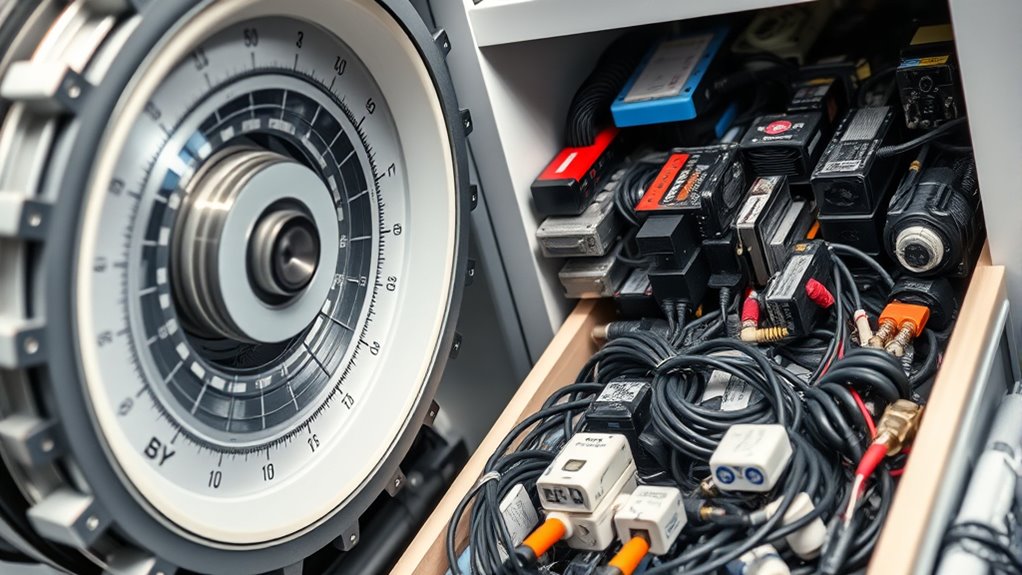

Compatibility and upgrade challenges can considerably impact your long-term investment in filter systems. If you choose a filter wheel, you might face software incompatibilities that limit integration with your existing control software or hardware. Upgrading to newer models can be complicated if they aren’t backward compatible, forcing you to replace entire systems instead of upgrading components. Physical constraints also pose issues, especially with filter drawers that may not fit into your setup or require modifications. These constraints can limit your options and increase costs over time. When planning upgrades, consider how well new systems will integrate with your current setup and whether physical constraints will restrict future expansion. Addressing these challenges upfront saves you time, money, and frustration later on. Additionally, understanding essential oils for compatibility can help optimize your system performance and maintenance routines.

Frequently Asked Questions

How Do Advanced Filter Wheels Impact Overall System Reliability?

Advanced filter wheels can enhance your system’s flexibility, but they may impact reliability if their filter wheel durability isn’t high. You might face increased maintenance requirements to guarantee smooth operation, especially with frequent use. To minimize issues, choose a filter wheel designed for durability, and schedule regular upkeep. This proactive approach helps maintain system reliability and prevents costly downtime caused by mechanical failures.

Are There Specific Brands With Fewer Upgrade Issues?

Think of choosing a filter wheel like selecting a sturdy bridge—some brands boast a reputation for durability, reducing the need for frequent upgrades. Brands like Thorlabs and Astro-Physics are known for their reliability and fewer upgrade issues, thanks to their strong reputation. You’ll find they require less maintenance and upgrade frequency, making your system more dependable and cost-effective over time. Picking a trusted brand guarantees smoother sailing on your observational journey.

What Are the Hidden Costs of Filter Wheel Calibration?

When it comes to filter wheel calibration, you might overlook the hidden costs, like ongoing maintenance expenses. Regular calibration ensures peak performance, but it requires time, effort, and sometimes specialized tools, which can add up over time. Failing to keep your filter wheel properly calibrated can lead to inaccuracies, increasing your maintenance expenses and risking equipment damage. Stay proactive by budgeting for these calibration needs to avoid costly repairs later.

Can Compatibility Issues Affect Imaging Accuracy?

Compatibility issues can definitely impact your imaging accuracy. If your filter wheel isn’t properly aligned with your sensor, you might experience misregistration or blurry images. Additionally, software compatibility problems can hinder your control over filter changes, causing delays or errors. To avoid these issues, verify your filter wheel is compatible with your camera and software, and regularly check sensor alignment to keep your imaging sharp and precise.

How Do Filter Wheel Costs Compare Over the System’s Lifespan?

Did you know filter wheel costs can be up to 30% higher over a system’s lifespan compared to drawers? In your cost analysis, you’ll find that advanced filter wheels often require more maintenance and replacement parts, increasing expenses over time. A thorough lifespan comparison shows that drawers tend to be more economical long-term, mainly due to fewer moving parts and simpler design, helping you save money and reduce downtime in your imaging setup.

Conclusion

Remember, the devil’s in the details. By understanding hidden costs and compatibility issues upfront, you can avoid unexpected expenses down the line. Advanced filter wheels and drawers each come with their own challenges, but with careful planning, you can minimize maintenance surprises. Don’t let hidden costs catch you off guard—think of it as building a house on solid ground rather than shifting sands. Stay informed, plan ahead, and save yourself trouble later.