Choosing between One Shot Color and Mono Safety gear depends on your needs. One Shot Color offers vibrant, customizable hues for easy visibility and quick hazard identification, making it great for dynamic environments. Mono Safety provides a sleek, uniform look with a focus on simplicity and cost-efficiency. Both prioritize safety and durability, but the right choice hinges on your environment and style preferences. Keep exploring to understand which option suits your safety requirements best.

Key Takeaways

- One Shot Color gear offers vibrant, customizable hues for quick identification, while Mono safety gear provides a sleek, uniform appearance.

- Color options in One Shot Color enhance visibility and hazard recognition, whereas Mono emphasizes simplicity and professionalism.

- Both styles prioritize safety and comfort, with material durability influencing long-term cost and environmental impact.

- Choice depends on visual style preference, work environment, and need for quick visual differentiation or a clean, professional look.

- Consider safety standards, environment suitability, and eco-friendly materials to select the most effective safety gear for your needs.

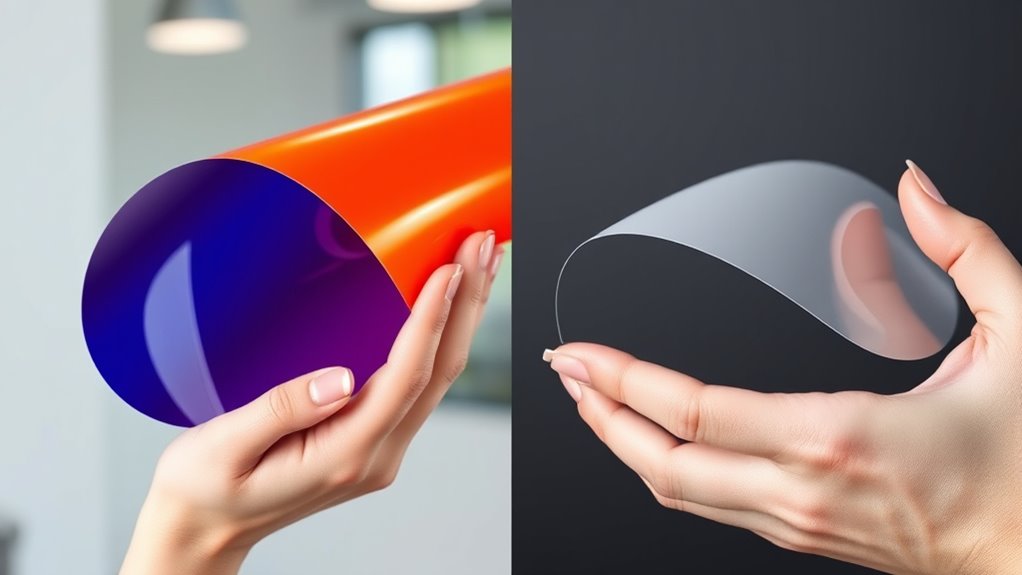

Overview of One Shot Color and Mono Safety Gear

When choosing safety gear, understanding the differences between One Shot Color and Mono options is essential. One Shot Color gear stands out with its vibrant, customizable hues that enhance aesthetic appeal, making it easier to identify team members or roles. Its ergonomic fit ensures comfort during long shifts, reducing fatigue and increasing safety. Mono safety gear, on the other hand, features a sleek, uniform appearance with a focus on simplicity and professionalism. While it may have a more understated look, Mono gear often offers a snug, ergonomic fit that aligns well with a variety of body types. Both options prioritize comfort and safety, but your choice depends on whether you prefer bold colors and visual distinction or a clean, minimal style. Additionally, selecting gear with proper maintenance can extend its lifespan and ensure ongoing safety.

Material Composition and Durability

You need gear that can withstand tough conditions, so pay attention to material quality and composition. High-quality materials resist wear and tear better, ensuring your safety lasts longer. Choosing durable gear means you won’t have to replace it frequently, saving you time and money. Additionally, selecting materials that are environmentally sustainable can help mitigate the negative impacts associated with deforestation and promote responsible resource use.

Material Quality and Composition

The material quality and composition of safety gear substantially impact its durability and performance. High-quality materials guarantee better chemical resistance, reducing damage from spills or exposure. They also minimize environmental impact by using eco-friendly components. When choosing gear, consider these key factors:

- The durability of the material under stress and environmental conditions

- Its ability to resist chemicals and corrosive substances

- The environmental impact of its production and disposal

- The consistency of material composition for reliable safety performance

- The use of specialized materials in construction to enhance longevity and safety features

Opting for well-constructed gear made from quality materials means you’ll benefit from longer-lasting protection, less environmental harm, and improved resistance in demanding conditions. Always check the composition to ensure it meets safety standards and aligns with your environmental values.

Resistance to Wear and Tear

Material composition directly influences how well safety gear withstands daily wear and tear. If the material has strong chemical resistance, it resists degradation from spills and exposure, extending its lifespan. Flexibility properties are equally important, allowing gear to move with you without cracking or tearing. Different materials excel in these areas:

| Material Type | Chemical Resistance | Flexibility Properties |

|---|---|---|

| Rubber | High | Excellent |

| Polyurethane | Moderate | Good |

| PVC | Good | Fair |

Choosing gear with the right combination guarantees durability and safety, keeping you protected longer through tough conditions. Understanding these factors helps you make smarter decisions for your safety needs. Additionally, selecting a preppy dog name that reflects your personality can be a fun way to express your style while ensuring your gear remains durable.

Visual Identification and Color Coding

Visual identification and color coding serve as quick and effective ways to distinguish between safety equipment, especially when time is critical. They enhance hazard recognition and guarantee you respond promptly. Here’s what you should keep in mind:

Using distinct, consistent colors for safety gear ensures rapid hazard recognition and prompt response.

- Use distinct colors to signal different hazards, making it easier to identify risks immediately.

- Confirm color choices follow ergonomic design principles, preventing confusion and reducing fatigue.

- Maintain consistency across equipment to build familiarity and improve response times.

- Regularly review and update color codes to reflect new hazards or safety standards.

- Adhering to best practices in security systems ensures that safety measures remain reliable and effective.

Ease of Application and Removal

When safety equipment is easy to apply and remove, it helps guarantee quick responses during emergencies. Color coding simplifies this process, allowing you to quickly identify and select the right gear. One shot color safety equipment often features straightforward application techniques, making it faster to don and remove without confusion. Variety of materials available can also influence the ease of use, ensuring the gear suits different environments and user needs. With clear color coding, you can streamline application, reducing errors and saving valuable seconds. Ease of removal is equally important, especially if you need to switch gear rapidly or exit a hazardous area. Overall, equipment designed for quick application and removal enhances safety by ensuring you get the right protection exactly when you need it, without unnecessary delays.

Safety Standards and Compliance

Ensuring your safety equipment meets established standards is crucial for reliable protection. Compliance guarantees that products have undergone rigorous testing, supporting your safety and the manufacturer’s brand reputation. To verify compliance, consider these steps:

- Check for certifications from recognized standards organizations.

- Review manufacturer documentation for safety data sheets.

- Confirm adherence to industry-specific regulations.

- Invest in extensive user training to understand proper usage.

- Recognize that creative practice can also enhance problem-solving skills related to safety procedures.

Suitable Environments and Use Cases

Choosing the right safety equipment depends heavily on the environment and specific use cases. For industrial environments, safety gear must withstand harsh conditions, while outdoor applications demand visibility and durability. One Shot Color safety gear enhances visibility in high-traffic areas, making it ideal where quick recognition is vital. Conversely, Mono safety equipment offers a professional look for controlled settings. Consider the following table:

| Environment | Use Case | Recommended Safety Gear |

|---|---|---|

| Industrial environments | Heavy machinery and work zones | Mono for professionalism |

| Outdoor applications | Construction sites, roadwork | One Shot Color for visibility |

| Indoor environments | Warehouses, factories | Both, depending on activity |

Evaluate your environment to choose the safest, most effective gear for your needs. Additionally, selecting safety gear made from high-quality materials can significantly improve its durability and protection over time.

Cost Considerations and Longevity

Cost is a crucial factor to take into account when selecting safety gear, as initial expenses can vary considerably between Mono and One Shot Color options. Your choice impacts long-term cost effectiveness and maintenance costs. Consider these points:

Choosing between Mono and One Shot Color gear affects both initial cost and long-term savings.

- Mono safety gear often has a lower upfront cost, making it budget-friendly initially.

- One Shot Color gear may cost more initially but offers better durability, saving money over time.

- Maintenance costs for Mono gear tend to be higher, as it may require frequent cleaning or replacement.

- One Shot Color gear’s longevity reduces the need for replacements, improving overall cost effectiveness.

- Additionally, understanding material durability can help you make an informed decision about the best long-term investment.

Ultimately, investing in more durable, long-lasting gear can provide better value and reduce ongoing expenses.

Choosing the Right Safety Gear for Your Needs

When selecting safety gear, it’s important to contemplate how your specific needs and work environment influence the best choice. Consider safety standards and the level of protection required, but also think about current fashion trends—wearing gear that’s comfortable and stylish can boost compliance. Additionally, evaluate the environmental impact of your options; eco-friendly materials reduce waste and support sustainability. Safety gear today combines function with fashion, allowing you to stay protected without sacrificing style. If you work outdoors or in demanding conditions, durability and visibility may be priorities. For indoor or less hazardous tasks, lightweight and breathable gear might suffice. Furthermore, incorporating sustainable fashion principles into your safety gear choices can promote eco-conscious practices in your workplace. Ultimately, choosing gear that aligns with your needs, fashion preferences, and environmental values ensures safety and satisfaction.

Frequently Asked Questions

How Do One Shot Color and Mono Safety Gear Impact Worker Visibility?

You’ll notice that one shot color safety gear enhances worker visibility through high color contrast, making you easily identifiable in busy environments. Mono safety gear, with its uniform branding and single color, can sometimes blend in, reducing visibility. Choosing the right gear depends on your work setting; bright, contrasting colors improve safety by ensuring you’re seen quickly, while consistent branding helps colleagues recognize your role easily.

Can One Shot Color Gear Be Used in Hazardous Chemical Environments?

Think of one shot color gear as a vibrant shield in a chemical lab. You can use it in hazardous chemical environments if it offers the necessary chemical resistance, ensuring safety against corrosive substances. Color coding helps you quickly identify hazards, but always verify that the gear’s material resists the specific chemicals you encounter. This way, you stay protected while maintaining clear visual cues for safety.

Are There Specific Industry Regulations Dictating Color Choices for Safety Gear?

Yes, industry standards and color coding regulations often dictate specific colors for safety gear, helping you easily identify hazards and roles. You must adhere to these guidelines to guarantee compliance and safety in your workplace. For example, certain colors are designated for fire safety, biohazard, or electrical areas. Always stay updated with local, national, or industry-specific standards to select the correct gear colors, reducing confusion and enhancing safety protocols.

How Do Environmental Factors Influence the Longevity of Safety Gear?

Environmental exposure greatly impacts the longevity of safety gear. For example, if you work outdoors, constant UV exposure can accelerate material degradation, weakening protective qualities over time. Water, chemicals, and extreme temperatures also hasten wear and tear, reducing effectiveness. To guarantee safety, regularly inspect gear for damage, especially after harsh environmental conditions, and choose materials designed to withstand specific environmental factors, thereby prolonging the gear’s lifespan.

What Are the Best Practices for Maintaining and Inspecting Safety Gear?

You should regularly conduct risk assessments to identify potential hazards and determine if your safety gear still provides adequate protection. Keep your PPE clean, dry, and stored properly, inspecting it before each use for damage or wear. Follow PPE training guidelines to ensure correct usage and maintenance. Replace any damaged or expired equipment promptly, and document inspections to maintain compliance and safety standards, reducing the risk of accidents.

Conclusion

Choosing between one shot color and mono safety gear is like selecting the right key for a lock—you need the perfect fit to guarantee safety and efficiency. Consider your environment, durability needs, and compliance requirements. When you pick the right gear, you’re not just locking safety in place; you’re opening the door to peace of mind. Trust your instincts, weigh your options, and secure your safety with confidence.