Before you start, it’s important to know that coverings and waterproof coatings don’t fully prevent dew, as trapped moisture can worsen condensation. Effective power routing depends on controlling humidity, ensuring proper insulation, and maintaining good ventilation. Avoid relying solely on dehumidifiers or seals; instead, focus on temperature regulation and moisture management. If you follow these guidelines, you’ll better protect your equipment from dew-related issues — continue to explore for essential tips and facts.

Key Takeaways

- Waterproof coatings alone do not prevent dew; managing humidity and temperature is essential.

- Proper power routing minimizes moisture exposure, prevents corrosion, and reduces dew formation risks.

- Sealing and insulating enclosures help block moisture ingress and maintain stable internal conditions.

- Adequate ventilation and environmental controls are critical for controlling humidity and preventing dew.

- Regular inspection and maintenance of seals, insulation, and ventilation systems are vital for effective dew prevention.

Common Misconceptions About Dew Prevention Techniques

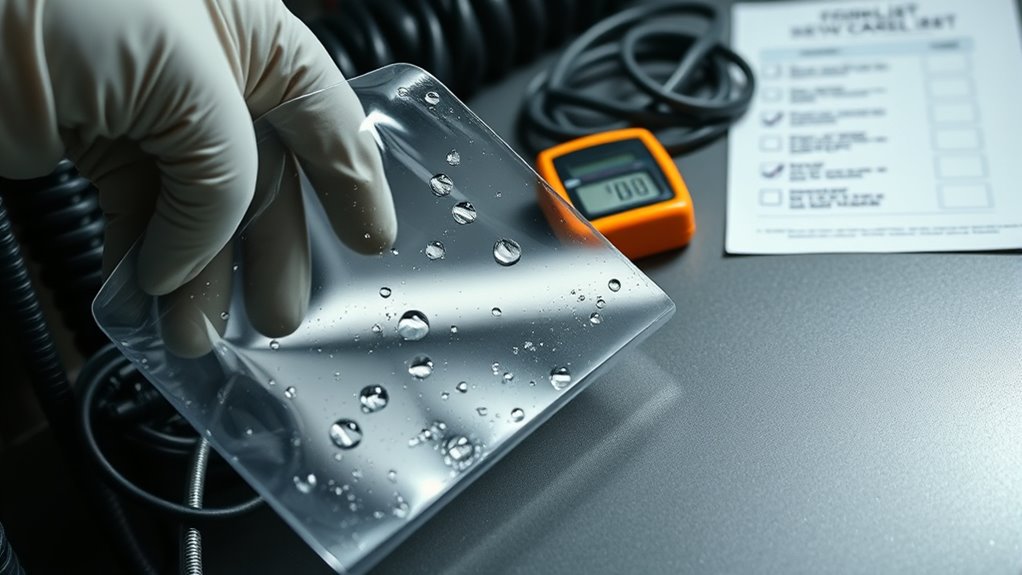

Many people believe that applying waterproof coatings or covering surfaces entirely will prevent dew formation, but these methods often fall short. While they may seem effective, dew is primarily driven by humidity management and condensation control. Coverings can trap moisture or create microclimates that encourage condensation, rather than prevent it. Waterproof coatings might repel water on the surface but don’t address the underlying humidity levels that cause dew to form. To effectively combat dew, you need to focus on reducing ambient humidity and managing temperature fluctuations that lead to condensation. Simply covering or waterproofing surfaces isn’t enough; understanding and controlling the environmental factors involved is essential for true dew prevention. Additionally, exploring Remote Hackathons can provide innovative ideas and technological solutions for environmental monitoring and humidity control.

Essential Factors for Effective Power Routing

Effective power routing hinges on understanding and implementing key factors that guarantee reliable and efficient electrical flow. Humidity control is essential, as excess moisture can lead to corrosion and short circuits. Maintaining proper environmental conditions minimizes dew formation and protects your wiring. Insulation strategies also play a pivotal role; using high-quality, appropriate insulation materials prevents moisture ingress and electrical leaks. Proper routing minimizes exposure to damp areas and reduces the risk of moisture-related issues. Additionally, ensuring tight, secure connections and avoiding unnecessary bends or stress points in cables enhance overall performance. By focusing on humidity control and effective insulation strategies, you create a resilient system that reduces downtime and prolongs equipment lifespan, ensuring your power routing is both safe and dependable.

Do’s and Don’Ts for Protecting Equipment From Moisture

To safeguard your equipment from moisture-related damage, it’s important to follow specific do’s and don’ts. Prioritize humidity control by maintaining ideal levels to prevent condensation. Avoid neglecting insulation strategies; proper insulation reduces temperature fluctuations that cause moisture buildup. Don’t ignore the importance of sealing enclosures and vents, as these prevent moisture ingress. Ensure that you regularly inspect and maintain seals, gaskets, and insulation materials. Don’t rely solely on dehumidifiers or ventilation—combine these with robust insulation to create a moisture-resistant environment. Additionally, consider using headphone jacks and connections that are resistant to moisture and corrosion to further protect your devices. Conversely, don’t overlook the significance of proper placement and avoiding areas prone to high humidity or water exposure. By implementing effective humidity control and insulation strategies, you minimize the risk of moisture damage and prolong your equipment’s lifespan.

The Role of Proper Ventilation and Environmental Controls

Proper ventilation and environmental controls are essential for maintaining ideal conditions that prevent moisture buildup and protect your equipment. Effective humidity control helps keep moisture levels low, reducing the risk of dew formation. Good airflow management ensures consistent air circulation, preventing stagnant pockets where humidity can accumulate. By regulating temperature and humidity, you create an environment less conducive to condensation. Proper ventilation also helps remove excess moisture and prevents mold growth, which can damage sensitive components. You should monitor environmental conditions regularly and adjust ventilation systems accordingly. Implementing these controls is a proactive step toward dew prevention, ensuring your equipment stays dry and functional. Additionally, understanding the role of AI in media and entertainment highlights how technological advancements can optimize environmental controls and device performance. Remember, maintaining proper airflow and humidity levels is key to protecting your gear from moisture-related issues.

Troubleshooting and Preventative Measures for Dew-Related Issues

When you notice signs of moisture or dew forming on your equipment, taking immediate troubleshooting steps can prevent further damage. Start by evaluating humidity control levels around your setup; high humidity encourages dew formation. Improve insulation strategies to reduce cold surfaces where dew can condense. Check for leaks or gaps that allow moisture intrusion, then seal or insulate those areas. Consider using desiccants or dehumidifiers to maintain ideal humidity levels. Regularly monitor environmental conditions to catch issues early. Incorporating soundproofing techniques can also help stabilize indoor temperatures and reduce dew risk.

Frequently Asked Questions

How Can I Identify Early Signs of Dew-Related Equipment Damage?

You can spot early signs of dew-related equipment damage by checking moisture indicators regularly. Look for corrosion symptoms like rust, discoloration, or pitting on metal surfaces, which signal moisture buildup. Keep an eye on connections and terminals for signs of corrosion or moisture intrusion. Address these issues promptly to prevent further damage. Regular inspection helps you catch problems early, reducing downtime and costly repairs caused by dew-related deterioration.

What Are the Long-Term Effects of Improper Power Routing on Equipment?

If you ignore proper power routing, you risk silent corrosion risks that slowly weaken your equipment. Over time, this can lead to unexpected equipment failure, leaving you stranded and facing costly repairs. The damage isn’t always visible at first, but the long-term effects threaten your system’s reliability and safety. Don’t wait for a breakdown—ensure your power routing is correct to protect your equipment and extend its lifespan.

Are There Eco-Friendly Methods for Dew Prevention and Moisture Control?

Yes, you can use eco-friendly methods for dew prevention and moisture control. Sustainable solutions like green technologies include using humidity sensors to automate dehumidifiers, employing natural absorption materials, and optimizing insulation with eco-friendly products. These methods not only reduce energy consumption but also minimize environmental impact, helping you maintain equipment efficiently while supporting environmental sustainability. Incorporate these green technologies to achieve effective moisture control responsibly.

How Does Seasonal Weather Variation Impact Dew Prevention Strategies?

Seasonal weather variation considerably impacts dew prevention strategies by requiring climate adaptation and addressing moisture variability. You need to adjust your methods, like increasing ventilation during humid seasons or using moisture barriers in colder months. As temperatures fluctuate, the dew point shifts, so staying flexible in your approach helps prevent dew formation effectively. Monitoring weather patterns allows you to adapt your moisture control techniques, ensuring consistent protection year-round.

Can DIY Solutions Effectively Replace Professional Moisture Management Systems?

DIY hacks can be helpful as budget solutions, but they usually can’t fully replace professional moisture management systems. You might see some improvement using simple methods like proper ventilation or moisture absorbers, but for consistent, long-term dew prevention, investing in expert systems is best. Professional setups are designed to handle complex moisture issues more effectively and reliably, saving you time and potential damage in the long run.

Conclusion

Think of your equipment as a delicate seed, needing the right conditions to flourish. By debunking myths and applying proven dew prevention techniques, you’re planting the roots for lasting performance. Proper routing, ventilation, and vigilant troubleshooting act as nourishing sunlight and water, guiding your gear through the storm. When you harness these essentials, you cultivate resilience—turning potential dew disasters into a flourishing landscape of reliability and success.