To maintain sensor size and pixel pitch safely, handle sensitively, and use proper cleaning techniques, always power down your equipment first. Use anti-static tools like gloves and static-free mats to prevent ESD damage. Avoid applying excessive force and use manufacturer-approved cleaning supplies. Regular inspection and organized workflows reduce risks, while correct calibration ensures ideal performance. Continue exploring these best practices to keep your sensor in top shape and avoid costly mistakes.

Key Takeaways

- Use ESD-safe tools and wear anti-static gloves when handling sensors to prevent static damage.

- Power down equipment before cleaning or maintenance to avoid electrical hazards.

- Handle sensors gently with proper tools to prevent scratches, oils, or physical damage.

- Keep workspace organized and tools sanitized to reduce contamination risks during maintenance.

- Follow manufacturer instructions precisely for cleaning, calibration, and firmware updates to ensure safety and performance.

Understanding Sensor Dimensions and Their Impact on Image Quality

Understanding the size of a sensor is vital because it directly influences the quality of your images. A larger sensor typically captures more light, resulting in better low-light performance and improved dynamic range. Sensor size affects the overall detail and clarity, with bigger sensors providing a shallower depth of field for artistic effects. Pixel pitch, which is the distance between pixels on the sensor, also plays an important role. Smaller pixel pitch allows for higher resolution, but can sometimes reduce light sensitivity, impacting image quality in low-light conditions. Conversely, larger pixel pitch enhances light gathering, leading to cleaner images with less noise. By understanding these factors, you can better evaluate camera options and guarantee your equipment meets your photography needs.

The Significance of Pixel Pitch in Sensor Performance

Pixel pitch, the distance between individual pixels on a sensor, directly influences how well your camera performs in various conditions. Smaller pixel pitch increases pixel density, boosting sensor resolution and detail capture, especially in low-light situations. However, very small pixels can reduce light sensitivity, leading to noisier images. Larger pixel pitch improves light gathering and dynamic range but may decrease overall resolution. Understanding this balance helps you select sensors that match your needs. Additionally, creative practice in sensor design can lead to innovative solutions that optimize both resolution and sensitivity for diverse shooting environments.

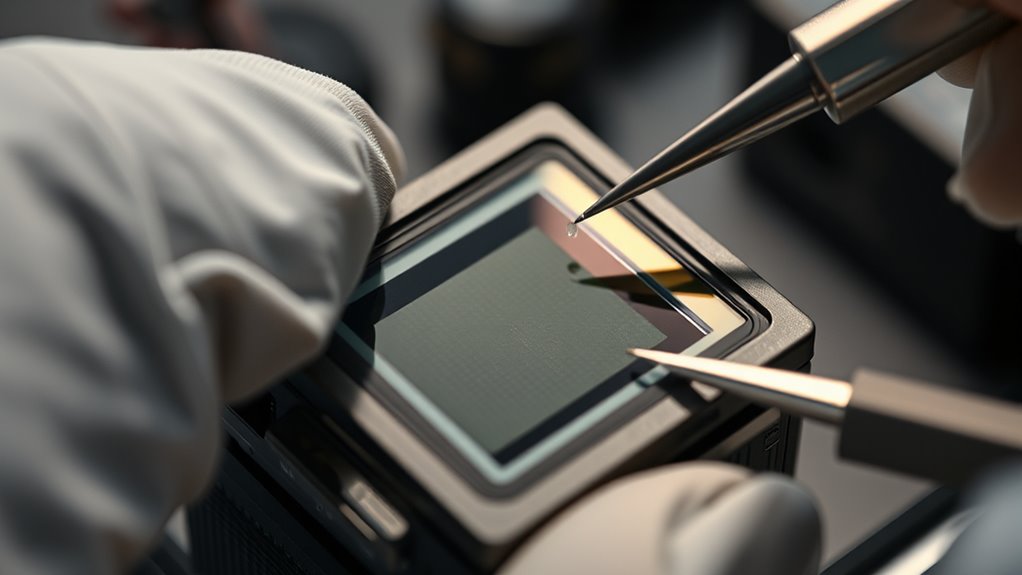

Proper Handling and Cleaning Techniques for Camera Sensors

Handling and cleaning your camera sensor carefully is essential to maintain image quality and prevent damage. Use a blower or soft brush to remove dust before any contact. For deeper cleaning, apply a specialized sensor cleaning solution with a lint-free cloth or sensor swab. Always perform sensor calibration after cleaning to ensure accuracy. Keep firmware updated to improve sensor performance and interface compatibility. Regular maintenance and awareness of industry trends help ensure optimal sensor longevity and functionality.

Common Risks and Precautions During Sensor Maintenance

When maintaining sensors, you need to be aware of common risks like electrostatic discharge that can damage delicate components. Protecting sensor surfaces from scratches and contaminants is essential to guarantee peak performance. Using proper tools and techniques helps you avoid accidents and keeps the sensor safe during maintenance. Additionally, understanding the importance of AI security vulnerabilities can help in developing safer maintenance protocols that prevent potential digital threats.

Handling Electrostatic Discharge

Electrostatic discharge (ESD) poses a significant risk during sensor maintenance because even a small static spark can damage sensitive components. Static electricity builds up easily on your body or tools, and a sudden discharge can ruin the sensor’s delicate circuitry. To prevent damage, always handle sensors in an ESD-safe environment. Use grounded wrist straps and anti-static mats, and avoid wearing static-prone clothing. Keep humidity levels moderate to reduce static buildup. Store sensors in anti-static bags when not in use. Be mindful of your movements and avoid unnecessary contact with internal parts. Additionally, understanding the importance of proper patch testing can help identify potential sensitivities before full application.

Protecting Sensor Surfaces

Protecting sensor surfaces during maintenance is essential to prevent damage that can compromise image quality and sensor longevity. You must avoid introducing sensor surface contamination, which can cause spots or streaks on images. Handle sensors with clean, lint-free gloves and use proper tools to minimize contact. Be cautious of dust, oils, and residues that can settle on the surface, leading to sensor surface degradation over time. Always work in a dust-free environment, and keep the sensor protected with covers or caps when not actively cleaning. Proper precautions help prevent scratches, smudges, or other physical damage that could impair performance. Maintaining a clean, safe work area ensures your sensor remains in excellent condition, avoiding costly repairs or replacements caused by avoidable surface contamination. Additionally, understanding sensor maintenance best practices can further help preserve its performance and lifespan.

Proper Tool Usage

Using the right tools correctly is crucial to prevent accidental sensor damage during maintenance. Improper use can lead to costly repairs and calibration errors. Always select precision tools designed for sensor work, such as anti-static brushes and non-abrasive cloths. Be cautious during firmware updates to avoid disconnecting cables or applying excessive force. When performing sensor calibration, ensure tools don’t scratch or damage delicate surfaces. Keep tools clean and properly stored to prevent contamination. Remember, using incorrect tools increases the risk of sensor misalignment and surface damage. Proper tool selection is essential for maintaining sensor integrity.

- Use only manufacturer-approved tools

- Avoid sharp or metallic objects near sensors

- Handle cables gently during firmware updates

- Keep sensor surfaces free of debris

- Follow manufacturer instructions for calibration procedures

Tools and Supplies for Safe Sensor Care

To care for your sensor safely, you need the right tools for cleaning and protection. Essential equipment includes soft brushes, lint-free cloths, and specialized cleaning solutions. Don’t forget protective gear like gloves and eye protection to keep both you and the sensor safe during maintenance. Using proper maintenance techniques ensures optimal sensor performance and longevity.

Tools for Sensor Cleaning

Maintaining a clean sensor requires having the right tools on hand, as using improper supplies can cause damage or leave residues. The key tools include sensor cleaning kits designed specifically for delicate surfaces and anti-static brushes that prevent static buildup. These tools guarantee safe removal of dust and particles without scratching or harming the sensor. When choosing cleaning supplies, always opt for high-quality, sensor-safe options to avoid costly repairs. Proper tools help you perform effective and safe cleaning, maintaining ideal image quality. Keep these essential items in your kit: vetted products for safety and effectiveness, such as sensor cleaning kits, anti-static brushes, blower bulbs, sensor swabs, and isopropyl alcohol (99%).

Protective Equipment Essentials

Having the right protective equipment guarantees your sensor stays safe during cleaning and handling. Wear anti-static gloves to prevent static damage during sensor calibration or firmware updates. Use dust-free microfiber cloths and blower brushes to remove particles without scratching the sensor surface. Eye protection shields your eyes from accidental splashes or debris. A clean, static-free workspace minimizes risks and guarantees precise calibration. Keep tools like sensor cleaning swabs and precision screwdrivers organized and sanitized. When performing firmware updates, disconnect power sources carefully, avoiding static buildup. Proper protective gear reduces the chance of damage, contamination, or errors during maintenance. Always double-check that your equipment is suitable for sensitive sensors, guaranteeing safe, effective cleaning and updates every time. Additionally, be aware of support hours for assistance with technical issues or urgent maintenance needs.

Best Practices for Preventing Damage During Maintenance

Preventing damage during maintenance requires careful handling and adherence to best practices. Always power down equipment before starting, and handle sensors with anti-static gloves to prevent static discharge. When performing sensor calibration, ensure you follow manufacturer instructions precisely to avoid misalignment or damage. Be cautious during firmware updates; use only official files and verify compatibility to prevent corruption. Keep your workspace clean and organized to avoid accidental impacts. Use the proper tools designed for delicate sensor components, and avoid applying excessive force. Regularly inspect equipment for signs of wear or damage before maintenance. Document each step to track adjustments and avoid redundant procedures. Incorporating industry best practices further minimizes risks and helps protect your sensors, ensuring smooth, safe maintenance procedures.

Frequently Asked Questions

How Often Should I Schedule Sensor Maintenance for Optimal Safety?

You should schedule sensor maintenance every 6 to 12 months to guarantee ideal safety. Regular calibration ensures accurate readings, while dust prevention keeps the sensor functioning properly. If you operate in dusty environments or notice any performance issues, consider more frequent checks. Consistent maintenance helps prevent malfunctions and extends your sensor’s lifespan, so stay proactive and don’t skip regular calibration and cleaning to keep everything running smoothly.

What Are Signs of Sensor Damage That Require Professional Inspection?

Like a cautious sailor noticing storm clouds, you should watch for signs of sensor damage such as corrosion or calibration drift. If you see inconsistent readings, unexpected noise, or reduced sensitivity, it’s time for a professional inspection. These issues often indicate underlying problems needing expert attention to prevent further damage. Regularly checking for corrosion and maintaining proper calibration keeps your sensor shipshape and ensures safety and accuracy.

Can I Use Household Cleaning Products on Camera Sensors Safely?

You shouldn’t use household chemicals for sensor cleaning, as they can damage your camera sensor. Instead, use specialized sensor cleaning solutions and tools designed for delicate electronics. Household cleaning products often contain chemicals that are too harsh and can leave residues or cause corrosion. Always follow the manufacturer’s instructions for sensor cleaning, and consider professional inspection if you’re unsure or uncomfortable cleaning it yourself.

Are There Specific Storage Conditions to Prevent Sensor Deterioration?

To prevent sensor deterioration, you should store your camera in a cool, dry place away from direct sunlight. Keep the sensor storage environment stable, avoiding high humidity and extreme temperatures, which can cause damage over time. Use protective caps on the lens and sensor when not in use, and avoid exposing your camera to dust or moisture. Proper storage conditions help maintain sensor performance and extend its lifespan.

How Does Temperature Affect Sensor Longevity During Maintenance?

You should be mindful of temperature during maintenance because high heat causes thermal expansion, which can stress sensor components and reduce longevity. Conversely, low temperatures can make materials brittle. Maintain a stable environment with humidity control to prevent condensation and corrosion. Keeping the temperature within recommended ranges guarantees the sensor’s longevity, minimizes thermal stress, and protects sensitive parts, ultimately extending your sensor’s lifespan.

Conclusion

By paying close attention to sensor size, pixel pitch, and proper handling, you create a gentle rhythm of care that keeps your camera in harmony. Using the right tools and techniques, you can softly navigate maintenance, avoiding any harsh disruptions. When you approach sensor care with patience and caution, you guarantee your equipment remains in smooth, reliable motion—ready to capture every moment with clarity and confidence.