If you’re looking into UV and IR cut products, understanding certification standards like ISO, ASTM, and CE is key to ensuring safety and effectiveness. Always check product labels for UV protection ratings, IR filtering symbols, and official certification marks. These indicate compliance with safety regulations enforced by agencies like UL and ISO, which oversee product quality and testing. Keep exploring to learn how to verify authenticity and select the best, certified products for your needs.

Key Takeaways

- Certifications like ISO, ASTM, CE, and RoHS ensure UV/IR cut products meet safety and performance standards.

- Recognize certification symbols and labels indicating compliance and UV/IR filtering effectiveness.

- Regular testing and inspections validate product durability and adherence to established safety regulations.

- Manufacturers must follow industry standards for materials, coatings, and performance benchmarks to ensure quality.

- Ongoing monitoring and re-testing are essential for maintaining compliance and product reliability over time.

Top picks for "basic compliance"

Open Amazon search results for this keyword.

As an affiliate, we earn on qualifying purchases.

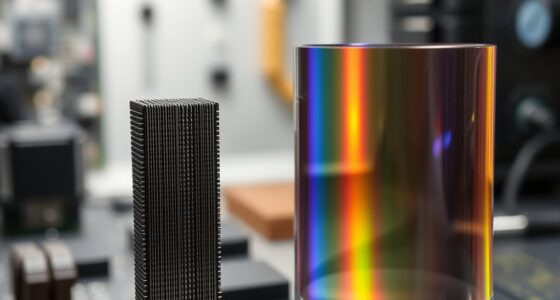

What Are UV and IR Cut Products?

UV and IR cut products are specially designed materials or coatings that block or filter ultraviolet (UV) and infrared (IR) radiation. These products enhance UV protection by reducing the amount of harmful UV rays that reach your skin or sensitive surfaces. They work through technologies like IR reflection, which deflects infrared radiation away from the material or area. This helps in maintaining cooler temperatures and protecting objects from heat damage. You’ll find UV and IR cut products in various applications, including window films, coatings, and textiles. Their main purpose is to improve safety and comfort by minimizing exposure to damaging radiation. UV and IR protection can also contribute to energy efficiency by reducing heat transfer through glass and other surfaces. Whether for automotive, architectural, or personal use, these products are essential for controlling UV and IR radiation effectively.

Common Standards and Certification Codes Explained

Understanding the standards and certification codes for UV and IR cut products is crucial to guarantee they meet safety and performance requirements. These codes ensure your products provide effective UV protection and IR filtering, reducing risks and improving reliability. Common certifications include international standards like ISO and ASTM, which specify testing procedures and performance benchmarks. Here’s a quick overview:

| Certification | Focus Area |

|---|---|

| ISO 12312-1 | UV protection in eyewear |

| ASTM G173 | Solar spectral data for IR filtering |

| CE Mark | European safety compliance |

| ANSI Z87.1 | Impact and UV safety for eyewear |

| RoHS | Restricts hazardous substances |

Ensuring compliance with these certification standards can help demonstrate your product’s reliability and safety to consumers and regulatory bodies.

Why Is Compliance Important for UV IR Cut Items?

Compliance guarantees that UV and IR cut products meet safety standards and perform effectively, protecting you from potential health risks and product failures. When products adhere to regulations, their material durability is assured, meaning they can withstand daily wear without degrading or losing effectiveness. This ensures long-term reliability and safety. Additionally, compliance supports aesthetic design, allowing UV IR cut items to maintain their appearance and fit seamlessly into your environment. Without proper standards, products may be prone to faster deterioration or compromised performance, risking your safety and satisfaction. Following compliance requirements helps you choose high-quality items that balance durability and design, giving you confidence in their effectiveness and longevity. Proper testing and certification processes ensure that the products have undergone rigorous quality control, safeguarding your health and investment in UV IR cut solutions.

How to Read and Interpret Product Labels and Codes

Learning how to read product labels and codes helps you verify UV and IR protection. You’ll need to recognize common symbols and understand what the product codes indicate. This knowledge guarantees you select items that meet your safety and compliance needs. Understanding automation trends can also help you stay informed about innovations that may influence product standards and labeling practices.

Deciphering Label Symbols

Have you ever looked at a product label and wondered what all those symbols and codes mean? Labels often include symbols indicating UV protection and IR filtering capabilities. Recognizing these symbols helps you choose the right product for your needs. For example, a shield symbol with “UV” indicates UV protection, while a wave with “IR” shows IR filtering. Here’s a quick guide:

| Symbol | Meaning | Key Feature |

|---|---|---|

| 🛡 UV | UV protection | Blocks harmful ultraviolet rays |

| 🌡 IR | IR filtering | Reduces infrared heat |

| 🔒 | Certification | Meets safety standards |

| ♻ | Recycling | Environmentally friendly |

| 🚫 | No | Indicates absence of a feature |

Understanding these symbols ensures you pick products that deliver best possible UV protection and IR filtering. Subtopic 1: Best Anime Movies

Understanding Product Codes

Product labels and codes provide essential information about a product’s features, safety standards, and usage instructions. When reading product codes, look for details indicating UV protection, such as UV rating or UPF numbers, which show how well the product shields against ultraviolet rays. These codes can also reveal product durability, guiding you on how long the item will last under regular use and exposure to elements. Manufacturers often include batch numbers or manufacturing dates, helping you verify authenticity and compliance with safety standards. By understanding these codes, you guarantee you select products that meet your UV IR cut needs, offering reliable UV protection and lasting durability. Accurately interpreting product labels helps you make informed decisions and maintain safety standards. Additionally, understanding the weight of wind turbine blades can be crucial when considering the durability and installation requirements of certain protective products.

Regulatory Agencies and Their Roles in Certification

Regulatory agencies set the certification standards your products must meet to guarantee safety and effectiveness. They oversee the compliance processes, conducting inspections and testing to enforce these rules. Understanding their roles helps you navigate the certification requirements more confidently. Additionally, knowledge of ethical hacking practices can aid in identifying potential vulnerabilities in the certification process itself.

Certification Standards & Agencies

Ever wonder which organizations guarantee UV and IR cut products meet safety and performance standards? Certification agencies set these benchmarks to ensure material durability and effective UV protection. They evaluate products through rigorous testing to verify compliance with safety codes. Astrological signs are sometimes considered in assessing perceived beauty, which these agencies do not evaluate, but it highlights the importance of trusted standards. Here’s a quick overview:

| Agency | Focus | Certification Type |

|---|---|---|

| UL (Underwriters Lab) | Material durability, safety standards | Product safety certification |

| CE (European Conformity) | UV protection, environmental compliance | CE marking |

| ANSI (American National Standards Institute) | Performance standards | Testing and certification |

| ISO (International Organization for Standardization) | International safety standards | Global certification |

These agencies help you select reliable UV IR cut products that meet essential safety and durability standards.

Compliance Processes & Oversight

Certification agencies don’t just set standards—they actively oversee and enforce compliance through detailed review and testing procedures. They verify that products meet manufacturing standards by examining design, materials, and construction. During testing, agencies evaluate UV and IR cut performance, ensuring products function as claimed. They also inspect manufacturing processes to confirm quality consistency and adherence to safety protocols. If a product passes testing and inspection, it receives certification, signaling compliance with relevant codes. Agencies maintain ongoing oversight by conducting random audits and re-testing to prevent deviations. This process helps protect consumers and ensure that UV IR cut devices perform reliably and safely, aligning with regulatory requirements. Understanding the role of compliance monitoring is essential for manufacturers seeking to meet these rigorous testing procedures and manufacturing standards to achieve and maintain certification.

Ensuring Quality and Safety Through Standards

To guarantee your UV IR cut products meet safety and quality standards, it’s essential to follow established industry guidelines and standards. These ensure your products deliver effective UV protection without compromising safety. Focus on material durability, selecting materials that withstand environmental factors like heat, UV exposure, and physical wear. Standards set by regulatory bodies specify testing methods and performance benchmarks, helping you verify that your products consistently perform as intended. Adhering to these standards minimizes risks of product failure and enhances consumer trust. Regularly review and update your manufacturing processes to align with evolving regulations. By prioritizing industry standards, you ensure your UV IR cut solutions are both safe and durable, providing long-lasting protection and peace of mind for your customers. Incorporating dynamic communication exercises can also improve team collaboration and ensure quality assurance practices are maintained.

Tips for Choosing Certified and Compliant UV IR Cut Products

When selecting UV IR cut products, prioritizing certified and compliant options guarantees you meet industry standards and regulatory requirements. Certified products ensure effective UV protection and IR filtering, safeguarding your eyes and equipment. To choose the right product, consider these tips:

- Verify certifications from recognized authorities like ANSI or ISO to confirm compliance.

- Check product labels for UV protection ratings and IR filtering specifications.

- Review manufacturer documentation for test results and safety data sheets.

Frequently Asked Questions

How Often Are UV and IR Cut Standards Updated?

UV and IR cut standards are updated periodically, usually every few years, to keep pace with technological advancements. You should stay informed about these updates because product certification requirements might change accordingly. Regular updates ensure that your products meet the latest safety and effectiveness standards, helping you maintain compliance and provide reliable protection. Keep an eye on industry announcements and regulatory bodies to stay current with the latest standards.

Are There Regional Differences in UV IR Cut Compliance Requirements?

Imagine you’re designing sunglasses for a global market. You’ll find regional variations in UV IR cut compliance requirements, as different countries adopt international standards at varying speeds. For instance, the European Union enforces stricter UV protection standards compared to some Asian markets. These regional differences reflect local regulations and consumer safety priorities, so you must stay informed about specific international standards to guarantee your products meet all regional compliance requirements effectively.

What Are the Penalties for Non-Compliance With UV IR Standards?

If you don’t comply with UV IR standards, you could face penalties like product recalls and legal liabilities. Non-compliance may lead to fines, lawsuits, or damage to your reputation. Regulatory agencies prioritize safety, so ignoring these standards puts your business at risk of costly consequences. To avoid these penalties, guarantee your products meet all UV IR cut requirements and maintain proper documentation for compliance verification.

How Can Consumers Verify a Product’s Certification Authenticity?

Like Sherlock Holmes examining clues, you can verify a product’s certification authenticity by checking for official labels or certification marks from recognized authorities. Always review the product certification details on the manufacturer’s website or contact them directly. Use authenticity verification tools or databases provided by certifying bodies. These steps guarantee you’re getting genuine UV IR cut products that meet standards, giving you peace of mind and protecting your investment.

Do Different Industries Require Distinct UV IR Cut Standards?

Yes, different industries do require distinct UV IR cut standards because of industry-specific regulations and material compatibility concerns. You need to check the standards relevant to your sector, such as medical, automotive, or electronics, since each has unique requirements. Ensuring your UV IR cut products meet these specific standards helps you stay compliant and guarantees the material compatibility necessary for safe and effective performance.

Conclusion

By paying close attention to labels, standards, and certifications, you subtly guarantee you’re choosing products that uphold quality and safety. Embracing these guidelines allows you to navigate the world of UV and IR cut items with confidence and grace, gently steering clear of potential pitfalls. Ultimately, your discerning eye and informed decisions create a seamless experience, where protection and compliance become an effortless part of your everyday choices—cultivating a safer, more reliable environment with elegance.