When choosing narrowband or broadband filters, you’ll rely on standardized codes indicating their features, such as bandwidth and frequency, to guarantee proper fit and performance. Compliance standards from organizations like IEC, ISO, and ANSI set testing and safety rules you must follow. Certifications like UL or CE confirm adherence, while regulatory bodies enforce these through inspections and audits. Staying informed about these codes and standards helps you select compliant filters. Explore further to learn more about maintaining regulatory compliance effectively.

Key Takeaways

- Filter codes specify type, bandwidth, center frequency, and design standards, aiding in proper selection and compliance.

- Industry standards like IEC, ISO, and ANSI define testing, safety, and electromagnetic compatibility requirements.

- Certification marks (e.g., CE, UL) confirm filters meet safety, performance, and regulatory compliance.

- Proper installation procedures ensure filters adhere to regulatory standards and maintain optimal performance.

- Understanding coding systems and standards helps ensure narrowband and broadband filters meet industry and legal requirements.

What Are Narrowband and Broadband Filters?

Narrowband and broadband filters are essential tools in various optical and communication applications. They play a crucial role in filter design, allowing you to select specific wavelengths or frequency ranges for your signal processing needs. Narrowband filters transmit a very limited range of wavelengths, making them ideal for isolating precise signals or reducing noise. Broadband filters, on the other hand, cover a wider spectrum, enabling you to process multiple signals simultaneously or capture broader data sets. Your choice depends on the application—whether you need high selectivity or broader coverage. Understanding these differences helps optimize performance in systems like telecommunications, imaging, and spectroscopy. By choosing the right filter type, you improve signal quality, enhance data accuracy, and ensure compliance with industry standards. Additionally, selecting appropriate filters can influence industry standards compliance and ensure reliable system performance.

How Do Narrowband and Broadband Filters Differ in Use?

You’ll notice that narrowband and broadband filters serve different purposes in signal reception, impacting their compliance and certification requirements. Narrowband filters target specific frequencies for precise communication, while broadband filters cover wider ranges for general use. Understanding these differences helps guarantee you meet the necessary regulations and optimize your system’s performance. Additionally, choosing the appropriate filter type can influence your ability to access best beaches and related recreational signals effectively.

Selective Signal Reception

While both narrowband and broadband filters are designed to select specific signals, they serve different purposes in how they handle signal reception. Narrowband filters focus on a very specific frequency, reducing signal attenuation from unwanted signals and noise, which helps you receive clearer signals. Broadband filters, however, cover a wider frequency range, allowing you to capture multiple signals simultaneously but with less precision. This makes broadband filters ideal for applications needing broader signal reception. The filter’s durability also plays a role; narrowband filters are often more delicate due to their precise tuning, while broadband filters tend to be more robust. Your choice depends on whether you prioritize signal clarity and selectivity or wider coverage and ruggedness. Additionally, understanding filter specifications is essential for selecting the right type for your needs.

Compliance and Certification

How do narrowband and broadband filters differ in compliance and certification requirements? Narrowband filters often require certification to specific standards due to their precise filter material, which demands rigorous testing to guarantee performance. Broadband filters, covering wider frequency ranges, must meet different certification criteria focused on broader signal handling and interference mitigation. Your installation techniques also influence compliance; improper mounting or incorrect use of filter material can lead to non-compliance. Manufacturers usually specify approved installation procedures that ensure the filter’s integrity and adherence to regulatory standards. Ensuring proper certification involves verifying the filter’s material quality and following recommended installation techniques to maintain compliance. Additionally, contrast ratio is a key factor that impacts the overall image quality and should be considered when selecting a filter to ensure optimal performance. Ultimately, understanding these differences helps you select the right filter and meet all necessary regulatory requirements.

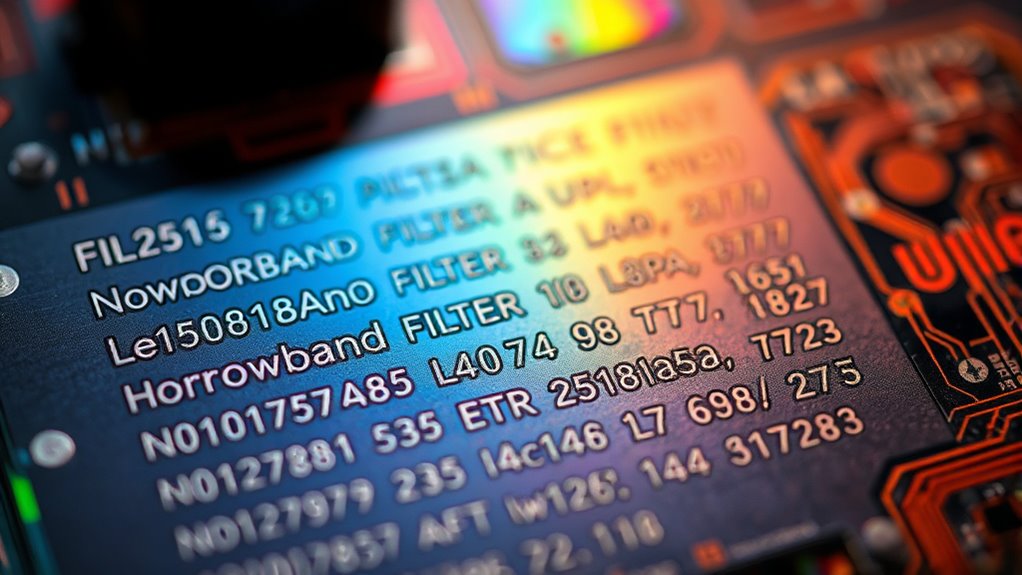

What Are the Common Coding Systems for Filters?

What are the common coding systems used for filters? In the world of filter design and signal processing, several coding systems help identify and categorize filters. The most common is the standardized alphanumeric code, which indicates filter type, order, and characteristics, like “BPF” for Bandpass Filter or “LPF” for Low Pass Filter. Another system uses frequency specifications, such as cutoff or center frequencies, often combined with quality factor (Q). Some codes specify filter topology, like Butterworth or Chebyshev, to guide performance expectations. These coding systems guarantee clear communication between designers, manufacturers, and users, simplifying the selection process. Understanding these systems helps you quickly grasp a filter’s purpose and design features, making signal processing tasks more efficient. Additionally, Ford Tuning techniques often utilize these coding standards to optimize performance modifications.

How to Read and Interpret Filter Codes?

Understanding how to read and interpret filter codes is key to quickly identifying a filter’s purpose and characteristics. These codes often encode information about filter design, such as bandwidth, center frequency, and optical density. By analyzing the code, you can determine if the filter meets your specific needs for narrowband or broadband applications. Manufacturers incorporate details about manufacturing processes into the coding system, reflecting quality and material choices. Pay attention to prefixes, suffixes, or numerical sequences—they often indicate the filter’s intended use, materials, and performance standards. Familiarizing yourself with these coding conventions allows you to efficiently select the right filter without needing extensive technical documentation each time. Clear interpretation ensures you match filters accurately to your system requirements. Additionally, understanding payment processing solutions can help streamline procurement and support ongoing supply chain needs.

Which Standards Regulate Filter Compliance?

Regulatory bodies set the rules that guarantee your filters meet safety and performance standards. Industry standards specify the technical requirements your filters must satisfy. Certification requirements confirm your products comply, helping you avoid legal issues and ensure reliability. Additionally, vetted product reviews can provide insights into compliance and performance from trusted sources.

Regulatory Bodies Overview

Various official organizations establish standards that guarantee filters meet safety and performance requirements. They guarantee your filter installation prevents signal interference and maintains ideal operation. These bodies set essential guidelines, including:

- The Federal Communications Commission (FCC) enforces limits on electromagnetic emissions to minimize interference.

- The International Electrotechnical Commission (IEC) develops standards for filter testing and safety.

- The European Telecommunications Standards Institute (ETSI) regulates broadband and narrowband filter compliance across Europe.

Relevant Industry Standards

Numerous industry standards govern the compliance of narrowband and broadband filters, ensuring they meet performance and safety requirements. These standards influence filter manufacturing processes and align products with market trends, helping manufacturers deliver reliable, high-quality filters. Key standards include IEC, ISO, and ANSI, which specify testing procedures, material safety, and electromagnetic compatibility. Staying current with these regulations guarantees your filters conform to international quality benchmarks, reducing the risk of non-compliance issues. As market trends shift toward higher performance and safety, adhering to these standards becomes even more critical. Additionally, the subtle effects of electromagnetic compatibility should be considered to prevent interference issues in sensitive applications. By understanding and applying relevant industry standards, you can ensure your filter products meet necessary regulations, satisfy customer expectations, and maintain competitiveness in a rapidly evolving market.

Certification Requirements

Understanding which standards regulate filter compliance is essential to guarantee your products meet industry requirements. Certification requirements focus on ensuring your filters’ filter material and manufacturing processes adhere to specific regulations. To achieve compliance, you should consider:

- Verifying that your filter material meets safety and performance standards set by organizations like the FCC or IEC.

- Ensuring your manufacturing processes follow quality management systems, such as ISO 9001.

- Conducting rigorous testing to confirm your filters meet electromagnetic interference (EMI) and radio frequency interference (RFI) requirements.

- Leveraging hackathon events as opportunities to collaborate with experts and stay informed about emerging standards and innovations in filter technology.

These steps help validate that your narrowband or broadband filters are compliant, reliable, and safe for market release. Staying updated on evolving standards guarantees ongoing conformity and reduces the risk of non-compliance penalties.

What Are the Key Regulations for Communication Filters?

Regulations for communication filters are essential to guarantee that these devices operate safely, effectively, and within legal boundaries. You must choose filter materials that meet specific safety and performance standards set by industry authorities. Proper installation techniques are also critical; incorrect installation can lead to signal interference or regulatory violations. Many regulations specify the types of filter material allowed and how they should be integrated into your system. Compliance often involves testing for emissions and ensuring that the filter does not obstruct or interfere with authorized communications. Staying updated on these key regulations helps you avoid penalties and ensures your communication filters function reliably. Always consult local and international standards to verify that your filter design, material, and installation meet all regulatory requirements.

How to Ensure Your Filters Meet Industry Standards?

To guarantee your filters meet industry standards, start by familiarizing yourself with the relevant regulations and testing requirements applicable to your region and application. Ensuring compliance involves three key steps:

Ensure your filters meet industry standards by understanding regulations, proper installation, and thorough testing.

- Verify that your filter material meets the specified quality and safety standards.

- Follow proper installation procedures to maintain performance and prevent failures.

- Conduct thorough testing to confirm the filter’s performance aligns with industry benchmarks.

- Additionally, using safe and non-toxic materials in your filters can help ensure they meet safety standards and reduce risks during operation.

Are There Specific Certifications Required for Filters?

You need to know if your filters require specific certifications to meet industry standards. These certifications are often mandated by regulatory agencies to guarantee safety and performance. Checking the applicable standards helps you stay compliant and avoid potential issues down the line.

Certification Standards for Filters

Certification standards guarantee that filters meet specific safety, performance, and quality requirements before they reach the market. These standards ensure your filter material and manufacturing processes adhere to strict guidelines, preventing subpar products. To verify compliance, look for certifications like:

- ISO standards, which assess material quality and manufacturing consistency.

- CE marking, indicating conformity with European safety directives.

- UL listing, ensuring the filter meets rigorous safety and performance criteria.

These certifications confirm that your filters are produced with reliable materials and controlled manufacturing processes. They also help you avoid potential safety hazards and ensure consistent performance. Always check for these certifications before selecting filters, ensuring they meet industry benchmarks and regulatory expectations.

Regulatory Agency Requirements

Regulatory agencies often set specific certification requirements to guarantee filters meet safety and performance standards. These standards ensure that the filter material used in manufacturing processes is reliable and consistent, reducing risks of failure or malfunction. Depending on your application, certifications may require compliance with industry-specific regulations, such as FCC, CE, or UL standards. You might need to demonstrate that your filters adhere to strict testing procedures for durability, electromagnetic interference, and safety. Certification often involves providing detailed documentation of manufacturing processes, including material sourcing and quality control measures. Meeting these requirements helps you avoid legal issues, ensures product reliability, and builds customer trust. Always verify the specific certifications relevant to your region and application to stay compliant.

How Do Regulatory Bodies Enforce Compliance?

Regulatory bodies actively monitor and enforce compliance through a combination of inspections, audits, and reporting requirements. They scrutinize your filter design and signal processing methods to guarantee adherence to standards. Here’s how they do it:

Regulatory agencies enforce compliance via inspections, audits, and reporting to ensure standards and spectrum integrity.

- They conduct random inspections, examining your equipment and testing for proper filter performance.

- Audits review your documentation, verifying that your design and manufacturing processes meet regulatory specifications.

- They require periodic reporting, where you submit performance data and compliance evidence, demonstrating your adherence to narrowband or broadband filter regulations.

These steps help regulatory agencies catch non-compliance early, guaranteeing your systems operate within legal limits and maintain spectrum integrity. Staying proactive with your filter design and signal processing details is vital to avoid penalties.

Tips for Selecting the Right Filter and Ensuring Compliance

Choosing the right filter begins with understanding your specific application requirements and guaranteeing your design aligns with relevant standards. Start by evaluating the appropriate filter material, considering factors like durability, frequency response, and environmental conditions. This ensures your filter performs reliably and stays compliant. Next, pay close attention to installation procedures; improper installation can compromise filter effectiveness and violate regulations. Follow manufacturer guidelines carefully, ensuring proper mounting, grounding, and connections. Confirm that the filter’s specifications meet the necessary codes for your industry, whether narrowband or broadband. Regular inspections and testing after installation help verify compliance and performance. By selecting suitable materials and adhering to proper installation procedures, you can optimize your filter’s function and maintain regulatory compliance effectively.

Frequently Asked Questions

What Are the Latest Updates in Filter Coding Standards?

You should stay informed about the latest filter coding standards, which include recent code updates affecting filter certification processes. These updates often refine compliance requirements, guaranteeing your filters meet current regulations. By regularly checking industry bulletins and standards organizations, you can adapt your practices to maintain certification. Keeping up with these changes helps you avoid compliance issues and ensures your filters perform reliably within the newest regulatory frameworks.

How Often Do Filter Compliance Regulations Change?

You won’t believe how often filter compliance updates hit your industry—it’s like a whirlwind! Typically, regulations for filter certification change every 1-3 years, but it can vary based on technological advances and regulatory shifts. Staying ahead means regularly checking for compliance updates and ensuring your filters meet the latest standards. This proactive approach helps you avoid costly non-compliance issues and keeps your products reliable and compliant.

Are There Regional Differences in Filter Regulation Requirements?

Yes, you’ll find regional variations in filter regulation requirements due to different local regulations. These variations mean you need to verify specific standards in each area where you operate or sell filters. Local regulations can affect compliance, testing, and certification processes. Staying informed about regional differences ensures you meet all necessary standards, avoiding compliance issues and ensuring your filters are approved for use in each specific market.

Can Outdated Filters Still Meet Current Compliance Codes?

Outdated filters are like old shoes—you might be tempted to keep them, but they don’t meet current standards. As a rule of thumb, a filter’s lifespan depends on usage and environment, but regular maintenance procedures can extend their effectiveness. However, if your filters are past their prime, they likely won’t meet current compliance codes. Always check for updates and replace them when necessary to guarantee you stay compliant and maintain peak performance.

What Are the Penalties for Non-Compliance With Filter Standards?

If you don’t meet filter standards, you face penalties like fines or product recalls due to non-compliance enforcement. Your filters must have proper filter certification to guarantee they comply with current regulations. Failing to adhere can also damage your reputation and lead to legal action. Staying updated on compliance enforcement and maintaining valid filter certification helps you avoid these penalties and ensures your products meet all necessary standards.

Conclusion

Guiding the world of filters is like steering a ship through a sea of codes and standards. By understanding the differences and keeping compliance in check, you guarantee your equipment sails smoothly and safely. Think of the right filters as your trusted compass—guiding you through industry regulations with confidence. Stay vigilant, follow standards, and your journey will be clear sailing, with your filters performing like a well-orchestrated symphony of precision and reliability.