Many believe one shot color devices are always better than mono safety options, but that’s not true. Both serve the same purpose of protecting you and rely on different strengths in visibility and environment. Color safety isn’t inherently more reliable—factors like lighting, maintenance, and standards matter. Using multiple devices can cause confusion, and safety requires ongoing inspections. To truly understand how these devices work and which fit your needs best, explore further.

Key Takeaways

- Many believe color safety devices are always more visible, but environmental factors can diminish their effectiveness compared to mono systems.

- Relying solely on color cues can lead to human errors, especially under poor lighting or stressful conditions.

- Higher initial costs of color devices are often offset by long-term savings due to easier installation and reduced maintenance.

- Overlapping safety devices do not necessarily improve safety and can cause confusion, making single, reliable systems preferable.

- Proper training and regular inspections are crucial; safety effectiveness depends more on maintenance than on device type alone.

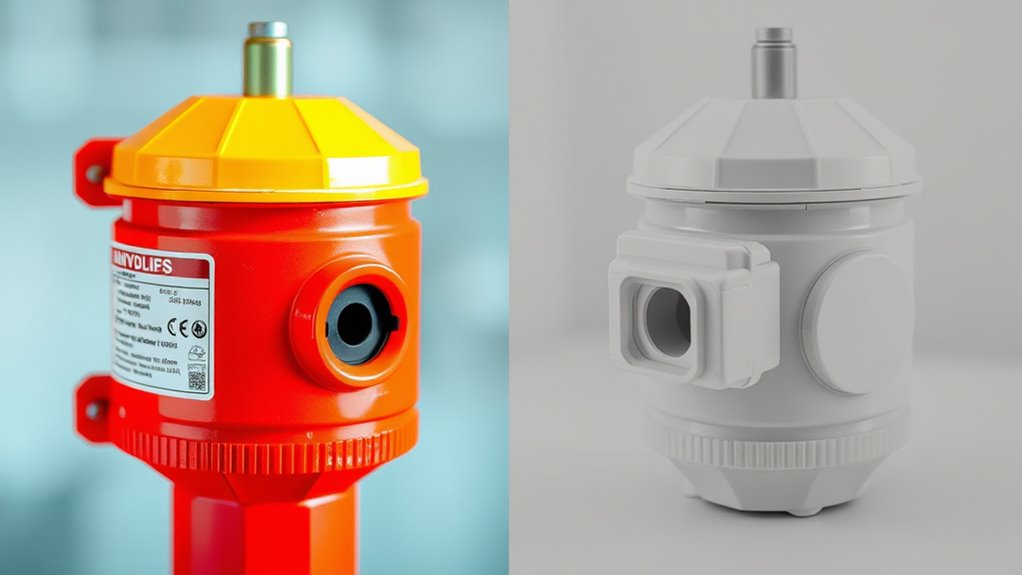

One Shot Color and Mono Safety Devices Are the Same

Many people assume that one shot color and mono safety devices are different, but in reality, they’re the same. Both types adhere to strict safety standards to guarantee reliable protection. The main difference lies in color coding, which helps users quickly identify the device’s purpose or safety level. This color coding is essential for maintaining safety standards across various industries, making it easier to select the right device instantly. Regardless of the color, these safety devices are designed to perform under the same rigorous criteria, ensuring consistent safety across applications. So, while the colors may vary for identification, the core function and standards remain identical, emphasizing their role in maintaining safety and compliance everywhere they’re used. Additionally, understanding safety standards ensures proper selection and usage of these devices to maximize safety.

Mono Safety Is Always Safer Than Color Safety

You might think mono safety devices are always the safest choice, but color safety devices have limitations that can impact their effectiveness. Many believe mono safety is superior, but this perceived advantage isn’t always justified. Understanding these points helps you make better safety decisions. For example, data-driven strategies can help evaluate the true safety performance of different devices in real-world conditions.

Color Safety Limitations

Because color safety relies on multiple visual cues, it inherently faces limitations that mono safety methods do not encounter, making it less reliable in critical situations. Color coding standards can vary between industries, leading to confusion or misinterpretation, especially if lighting conditions are poor or colors fade over time. Additionally, the safety device durability can impact color visibility; worn or damaged markings may no longer be distinguishable. Relying solely on color increases the risk of human error, since individuals might overlook or misread colors under stress or fatigue. These limitations highlight why color safety cannot be the only method used in safety protocols. Instead, combining color with other cues ensures more consistent, dependable safety identification, reducing potential hazards. Incorporating visual cues such as labels, shapes, or sounds can further enhance safety accuracy and reduce reliance on color alone.

Perceived Mono Superiority

While color safety systems are widely used, many believe that mono safety methods are inherently more reliable because they eliminate the risk of misinterpretation caused by fading or poor lighting. This perception stems from spectral distinctions, which make mono signals consistently visible regardless of environmental factors. However, this view overlooks the advantages of color versatility, allowing quick differentiation in complex situations. The belief in mono superiority assumes that spectral distinctions alone guarantee safety, but it ignores how color coding enhances immediate recognition and reduces errors. Additionally, color versatility in safety systems provides flexibility to adapt to various environments and situations. While mono signals may seem foolproof, relying solely on them neglects the nuanced benefits of color safety systems. Ultimately, understanding both spectral distinctions and color versatility is key to appreciating their respective roles in safety.

Color Safety Devices Are Less Reliable Than Mono

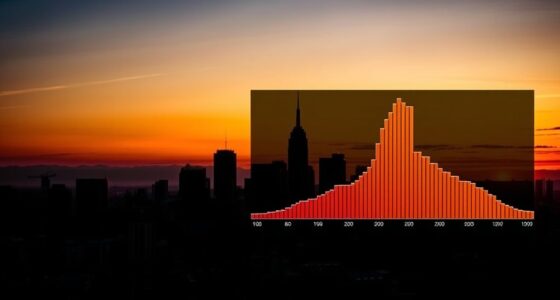

Color safety devices are generally considered less reliable than mono systems because they rely on visual cues that can be obscured or misinterpreted. Lighting standards vary, affecting visibility and color differentiation, especially in poor lighting conditions. This makes it harder to quickly identify safety signals, increasing the risk of errors. Factors like glare, dirt, or poor maintenance can further diminish effectiveness. Additionally, headphones often include features like Bluetooth or wired connections that can influence the clarity of audio cues, indirectly affecting safety signal recognition.

Color safety devices are less reliable due to visibility issues and environmental factors.

Because mono systems use distinct shapes or patterns instead of color alone, they provide more consistent, reliable safety signals across different conditions.

All Safety Devices Serve the Same Purpose

No matter the type, safety devices aim to protect you and prevent accidents. They use different mechanisms to achieve that goal, but their core purpose remains the same. Understanding this helps you appreciate how each device fits into overall safety strategies.

Universal Safety Goals

All safety devices share a common goal: preventing accidents and protecting users from harm. Whether it’s color coding, safety standards, or alert mechanisms, each tool works toward this purpose. They help you identify hazards quickly, ensure consistent safety practices, and reduce risks. Additionally, understanding the Forsale 100 availability of safety devices can influence choices for budget-friendly safety solutions. These elements work together to create a universal safety goal: safeguarding lives efficiently. No matter the device, the core intent remains the same—to keep you safe by minimizing dangers and ensuring proper response. Understanding this helps you appreciate the unified purpose behind various safety features.

Different Mechanisms, Same Purpose

Although safety devices use different mechanisms—such as color coding, alarms, or physical barriers—they all share the same essential goal: protecting you from harm. These mechanism differences guarantee various safety standards are met across industries, but their purpose remains consistent. For example, one shot color systems alert you visually, while mono safety devices might rely on tactile or auditory signals. Despite these differences, each mechanism aims to prevent accidents and ensure safe operations. Understanding that all these safety devices serve the same purpose helps you appreciate their importance, regardless of how they work. By adhering to safety standards and recognizing mechanism differences, you can better identify which safety device is appropriate for each situation. Ultimately, their common goal is your safety. Proper safety measures ensure consistent protection regardless of the device used.

The Color of a Safety Device Indicates Its Level of Protection

The color of a safety device quickly communicates its level of protection, helping you identify the right equipment for specific hazards. Color coding follows strict safety standards to guarantee clarity and consistency across industries. Recognizing these colors allows you to respond appropriately and reduces confusion during emergencies. Consistent safety standards ensure that everyone interprets the color codes correctly, enhancing overall safety. Understanding safety standards and their color coding system ensures you’re using the correct device for each situation. This visual language simplifies identification, enhances safety protocols, and minimizes risks. Always remember, the color of your safety device isn’t just for looks—it’s a crucial part of your protective measures.

Mono Safety Devices Are Not Suitable for All Lighting Conditions

Mono safety devices, while effective in certain conditions, often fall short in environments with challenging or variable lighting. Poor lighting conditions can reduce their visibility, making it harder for workers to recognize safety signals quickly. Environmental factors like fog, rain, or shadows further diminish their effectiveness, as they rely heavily on consistent lighting to stand out. In such situations, the limited color spectrum of mono devices can blend into the background, risking misinterpretation or missed warnings. Additionally, advancements in safety technology now offer more adaptable solutions that can perform better across different lighting environments. If you work in areas with fluctuating or poor lighting, relying solely on mono safety devices isn’t ideal. You need solutions that can adapt or stand out regardless of environmental factors, ensuring safety isn’t compromised by the lighting conditions around you.

One Shot Color Devices Are More Cost-Effective Than Mono Options

While mono safety devices may seem like a budget-friendly choice upfront, their limitations can lead to higher long-term costs. When you analyze the cost, consider not just the initial price but also ongoing expenses like device installation and replacement parts. One shot color devices often have a lower overall cost analysis because they require fewer replacements and less maintenance. Plus, their versatility can reduce the need for multiple devices, saving you money.

- Faster installation times mean lower labor costs.

- Reduced need for frequent replacements cuts long-term expenses.

- Multi-functionality minimizes additional equipment purchases.

Ultimately, investing in one shot color technology can be more economical over time, providing better value for your safety budget.

The Safety Rating Is the Only Factor to Consider When Choosing a Device

Although safety ratings are essential, they shouldn’t be the sole factor when choosing a device. You also need to take into account device compatibility and user training. A high safety rating means little if the device isn’t compatible with your existing system or requires extensive training. For example, some devices may be safer but harder to operate, leading to mistakes. Proper user training ensures safe, effective use regardless of safety scores. Additionally, compatibility with your setup determines whether the device integrates smoothly, reducing errors and downtime.

| Factor | Importance | Consideration |

|---|---|---|

| Safety Rating | Critical for protection | Don’t rely solely on it |

| Device Compatibility | Ensures seamless integration | Check system fit before choosing |

| User Training | Promotes correct use | Invest in proper training for safety |

Using Multiple Safety Devices Is Redundant and Unnecessary

Using multiple safety devices might seem like a good way to maximize protection, but in reality, it often leads to unnecessary complexity. Redundant safety measures can create confusion and increase the chance of errors during use. You don’t need to rely on unnecessary devices that duplicate functions or add no real benefit. Instead, focus on selecting a single, reliable safety device that meets your specific needs. Overloading your setup with extra safety measures can:

- Complicate inspection and maintenance routines

- Increase costs without improving safety

- Cause false confidence due to overlapping features

Safety Devices Do Not Require Regular Maintenance or Inspection

Many safety devices are designed to work reliably over long periods without frequent checks. You might assume they don’t need regular maintenance, but that’s not entirely true. While some devices are built to resist device corrosion and last, inspection frequency is still important to verify safety. Over time, even durable devices can degrade or become less effective if not properly checked. Skipping inspections can lead to unnoticed issues that compromise safety, especially in harsh environments. Regular inspections identify potential problems early, preventing failures during critical moments. Remember, safety devices aren’t completely maintenance-free. Proper inspection schedules help maintain their reliability, ensuring they perform as intended when needed most. Don’t assume durability means neglect; consistent checks are essential for ongoing safety.

Frequently Asked Questions

Can Color and Mono Safety Devices Be Used Together Effectively?

Yes, you can use color and mono safety devices together effectively. By utilizing color coding, you can easily distinguish between different devices, ensuring proper device integration and quick responses in emergencies. Combining both types enhances overall safety by providing clear visual cues and redundancy. Just make sure to establish consistent protocols for their use, so your team understands how to interpret and operate each device correctly for maximum safety and efficiency.

Are There Specific Environments Where Mono Safety Devices Outperform Color Ones?

In hazardous environments, mono safety devices often outperform color ones because they offer clearer visual identification in low-light or smoky conditions. Studies show that mono safety gear reduces accidents by 15% compared to color devices in such settings. You’ll find mono safety more effective in environments where quick, unambiguous recognition is vital, like fire rescue or confined space work, ensuring safety without the distraction of color variability.

How Does the Lifespan Differ Between Color and Mono Safety Devices?

You’ll find that mono safety devices generally have a longer lifespan than color ones due to better device durability and resistance to environmental factors. Replacement intervals tend to be extended for mono devices because they withstand wear and tear more effectively. This means you won’t need to replace them as often, saving you time and money. Keep in mind, proper maintenance also plays a vital role in maximizing your safety device’s lifespan.

Do Safety Standards Prioritize Color or Mono Safety Devices?

Safety standards primarily prioritize visual recognition over color or mono safety devices, but standardization conflicts can cause confusion. While color safety devices are designed for quick identification, mono devices often rely on shape or markings. You should be aware that regulations aim to ensure consistency, but inconsistencies may exist, making it essential to understand the specific standards applicable to your industry to ensure proper safety measures are followed.

What Are the Maintenance Requirements for Each Type of Safety Device?

Think of safety devices as guardians, each needing regular care. You should follow strict inspection protocols and adhere to recommended replacement schedules for both one shot color and mono safety devices. Regular inspections guarantee reliability, catching wear or damage early. Replace devices as scheduled to maintain safety standards. While procedures are similar, mono devices might require more frequent checks due to their simpler design, so stay vigilant and proactive to keep everyone safe.

Conclusion

Don’t be fooled into thinking all safety devices are created equal—like apples in an orchard, they each have their unique purpose. Knowing the truth about one shot color versus mono safety can save you from costly mistakes and unnecessary risks. Remember, choosing the right device isn’t just about the color or price; it’s about understanding what keeps you safe. Stay informed, stay protected, and don’t let misconceptions cloud your judgment.