Many believe that higher fuse ratings mean better protection, but that’s a myth; choosing the correct fuse involves understanding your circuit’s current needs to prevent damage and safety risks. Using incompatible connectors or reusing blown fuses can cause overheating, failures, or fires, so always verify ratings and replace with new, proper components. Good wiring practices and adherence to safety standards are key. Keep exploring to discover essential tips that safeguard your electrical setups effectively.

Key Takeaways

- Proper fuse ratings are crucial; higher ratings do not always mean better protection and can harm system safety.

- Always replace blown fuses with new, correctly rated ones; reuse can degrade safety and protective performance.

- Using connectors rated for the specific current and voltage prevents overheating and electrical failures.

- Correct wiring practices, including secure connections and insulation, are vital for electrical safety.

- Following safety standards and manufacturer guidelines ensures reliable operation and reduces risks of fire or damage.

Common Misconceptions About Fuse Ratings and Safety

Are you sure you understand how fuse ratings work and what they mean for safety? Many people believe that a higher fuse rating always provides better protection, but that’s a misconception. Using a fuse with an incorrect rating can shorten its lifespan or cause system damage. Fuse ratings aren’t just about maximum current; they also influence how long the fuse lasts before needing replacement. Additionally, connector compatibility is vital—using a fuse that doesn’t match the connector type can lead to poor contact or failure. Remember, a fuse rated too high might not blow when needed, risking damage, while one rated too low may blow prematurely. Understanding these details helps guarantee your system remains safe, reliable, and efficient. Vetting standards ensure you select the right fuse for your specific application.

The True Purpose of Fuses and How They Protect Circuits

Fuses are designed to protect your circuits from overcurrent conditions. When too much current flows through, the fuse blows, stopping the flow and preventing damage. This simple safeguard helps keep your electrical systems safe and functioning properly. Regularly inspecting and replacing blown fuses is essential for maintaining electrical safety and ensuring reliable operation.

Overcurrent Protection Role

Overcurrent protection is the primary function of fuses and other safety devices, designed to prevent damage to electrical circuits when excessive current flows through them. When circuit overloads happen, the current exceeds safe levels, risking overheating and component failure. Fuses act as a barrier, breaking the circuit before damage occurs. They do this by melting quickly when current surpasses their rated capacity. Over time, fuse deterioration can reduce their effectiveness, making them less responsive to overloads. That’s why choosing the right fuse and replacing it when needed is essential. Your goal is to guarantee that, in the event of an overload, the fuse will trip reliably, protecting your wiring, devices, and preventing potential fire hazards. Understanding the importance of attention in creative practice can also help you develop better troubleshooting skills when maintaining electrical safety.

Preventing Circuit Damage

When a circuit experiences an overload, the risk isn’t just damage to the fuse itself but to the entire electrical system. Circuit overloads cause excessive current flow, which can heat wires, damage components, and even cause fires. That’s where understanding fuse ratings becomes essential. Fuses are designed with specific ratings to match the circuit’s current capacity; selecting a fuse with an appropriate rating ensures it will blow before damage occurs. If the fuse rating is too high, it won’t trip during overloads, risking serious damage. Conversely, a fuse rated too low might blow prematurely, disrupting your system. Proper fuse ratings act as a safeguard, preventing circuit overloads from causing long-term damage and maintaining the safety and integrity of your electrical system. Additionally, AI-powered safety systems are increasingly being integrated to monitor electrical loads and alert users to potential overload conditions before damage occurs.

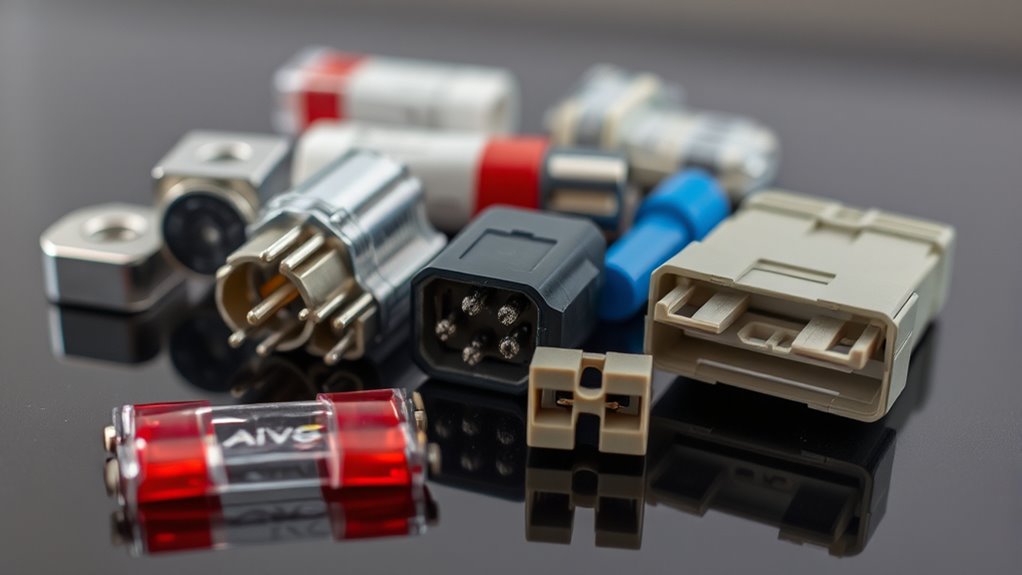

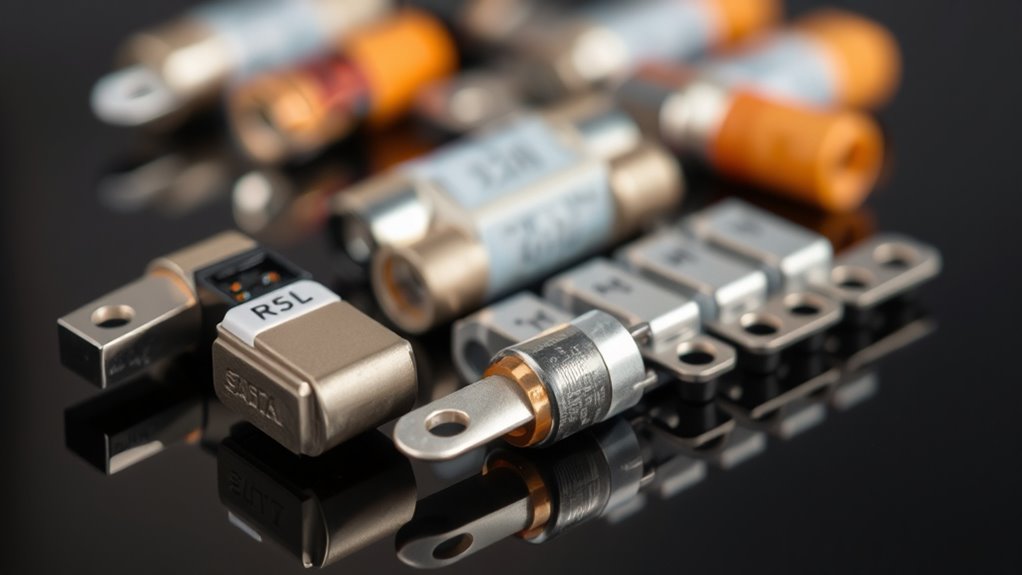

Selecting the Right Fuse for Your Application

Choosing the right fuse for your application is essential to guarantee safety and proper circuit protection. Fuse selection depends on understanding your circuit’s current and voltage requirements. You need to pick a fuse rated slightly above your normal operating current but below the point where components might be damaged. Compatibility with your connectors is also critical; ensure the fuse fits securely and maintains reliable connection. Consider the fuse type—cartridge, blade, or resettable—based on your setup. Proper fuse selection prevents nuisance blows and ensures quick response during faults. Always check manufacturer specifications for connector compatibility and electrical ratings. Using the correct fuse not only protects your equipment but also minimizes safety risks, giving you peace of mind that your system operates reliably under various conditions. Additionally, understanding the importance of creative thinking can help you approach troubleshooting and system design with innovative solutions.

Myths Surrounding Fuse Replacement and Reuse

Many people believe reusing fuses is safe, but that’s a dangerous myth. Reusing a blown fuse can lead to system failure or fire risks. Choosing the correct replacement fuse is essential for safety and proper operation. Additionally, understanding the proper fuse selection based on the electrical load and environment is crucial to prevent hazards.

Reusing Fuses Risks

Reusing fuses might seem like a cost-saving shortcut, but it’s a risky practice that can lead to serious safety issues. When you reuse a fuse, the fuse material may have degraded, reducing its ability to break the circuit safely during overloads. This compromises connector durability and increases the chance of electrical fires. Additionally, the contrast ratio of a projector influences how well dark scenes are rendered, which is critical for a true cinematic experience.

| Risk | Explanation |

|---|---|

| Fire hazard | Worn fuse material may fail to interrupt a fault properly, causing overheating. |

| Equipment damage | Reused fuses might not protect sensitive components effectively. |

| Unreliable operation | Old fuses can blow prematurely or not at all. |

| Safety compromise | Reusing fuses can hide wear and tear, risking your safety. |

Always replace a blown fuse with a new one to ensure maximum safety and performance.

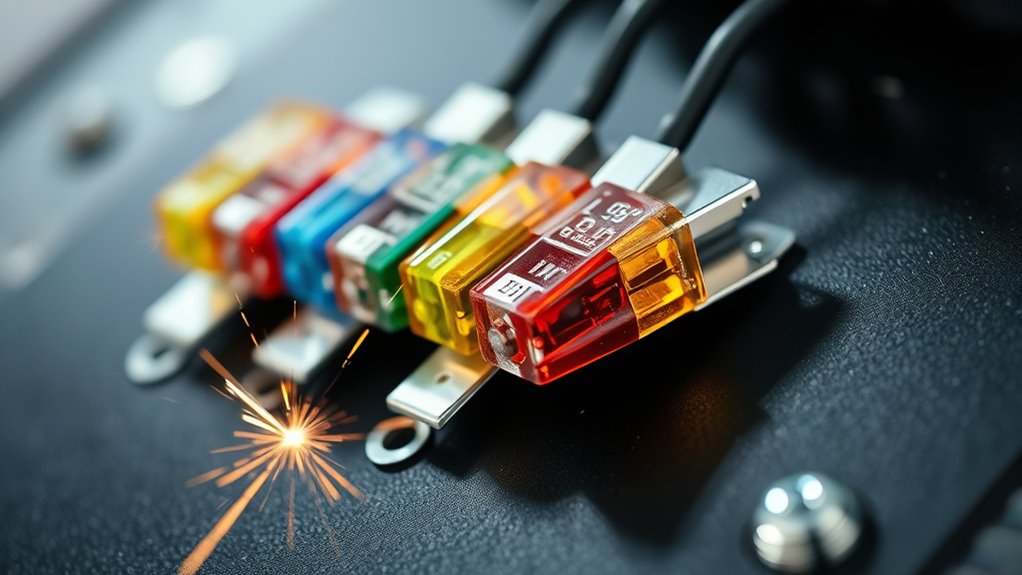

Myth: Replacing Is Safe

Some believe that simply replacing a blown fuse is a safe and straightforward fix, but this myth can lead to serious safety risks. Using a fuse with the correct fuse color is essential, as it indicates the proper amperage and helps prevent overloads. Replacing a fuse with one of a different connection size or incorrect rating can cause electrical shorts or fires. Never assume that any fuse can be swapped out without checking specifications. Even if the fuse looks intact, it might not match the original in terms of size or capacity. Always verify the fuse color and connector size before replacing. Relying on a quick fix without understanding the proper fuse details can compromise your safety and damage your system. Understanding fuse ratings is crucial to ensure safe and effective replacements.

Proper Fuse Selection

Proper fuse selection is essential for maintaining electrical safety and system reliability. You must guarantee fuse compatibility with your system’s voltage, current, and circuit type to prevent failures or hazards. Using an incompatible fuse can lead to overheating, equipment damage, or electrical fires. Additionally, choosing a fuse that matches the connector insulation specifications helps protect against accidental contact or short circuits. Never assume a fuse can be reused or substituted with one of a different rating; each fuse is designed for specific safety parameters. Proper fuse selection keeps your electrical system protected and functioning efficiently. Always verify specifications, follow manufacturer guidelines, and avoid shortcuts. This careful approach minimizes risks and ensures your system remains safe and reliable. Incorporating proper fuse maintenance is crucial for ongoing safety and performance.

Connector Types and Their Safety Considerations

Understanding the different types of connectors is essential for ensuring safety when working with electrical systems. You need to be aware of connector materials, as some are more durable and resistant to environmental factors, reducing risk. For example, connectors made from high-quality metals and plastics provide better safety margins. Connector insulation is equally crucial; it protects against accidental contact with live conductors and prevents short circuits. Proper insulation materials—such as rubber or thermoplastic—must be used for the application’s voltage and current levels. Using connectors with inadequate insulation or poor-quality materials can lead to overheating, arcing, or electrical failures. Always verify that your connectors meet safety standards and are suitable for your specific electrical system to minimize hazards. Additionally, understanding efficient general ledger coding can help organizations maintain accurate records of electrical component inventories and costs.

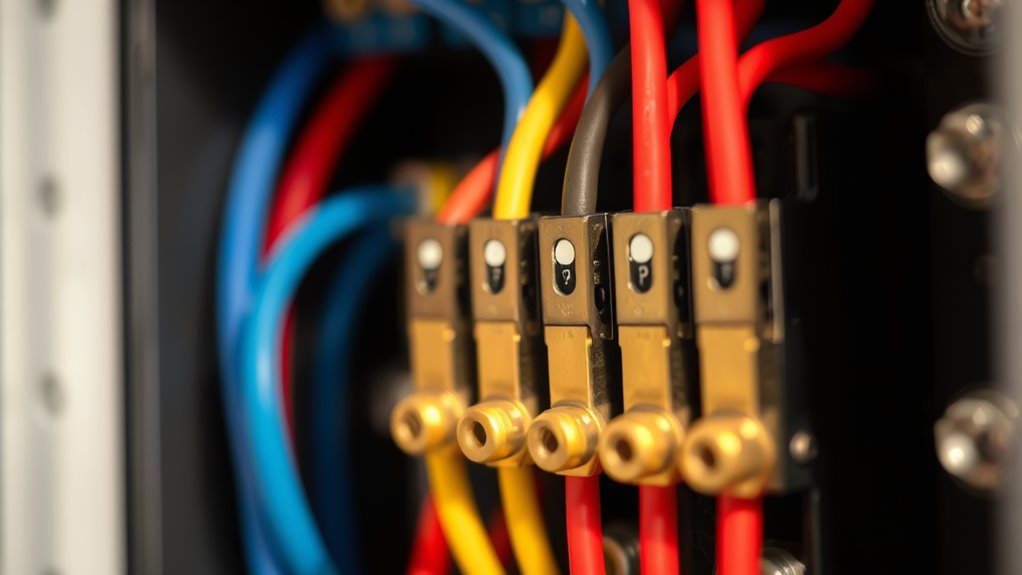

Proper Wiring Practices for Safe Connections

To guarantee safe electrical connections, you must follow proper wiring practices that prioritize secure and reliable setups. Ensure circuit grounding is solid to prevent shocks and equipment damage. Use high-quality insulation to maintain insulation integrity, avoiding exposed wires and shorts. Properly tighten connections to reduce resistance and overheating. Check for damaged wiring regularly. When wiring, follow color codes and specifications. Avoid shortcuts or mixing wire types. Remember, a well-grounded circuit and intact insulation protect everyone.

| Safety Factor | Critical Action | Potential Consequence |

|---|---|---|

| Grounding | Verify circuit grounding | Electric shock or fire |

| Insulation Integrity | Inspect insulation regularly | Short circuits, fires |

| Proper Tightening | Secure connections firmly | Loose connections, overheating |

| Correct Wiring | Follow color codes and standards | Miswiring, failure |

| Regular Checks | Conduct routine inspections | Hidden faults, hazards |

The Importance of Correctly Rated Connectors and Terminals

Using connectors and terminals that aren’t rated for your specific electrical load can compromise safety and equipment performance. When you choose the right ratings, you guarantee better connector durability, reducing the risk of failure over time. An underrated connector may overheat or melt, leading to dangerous shorts or fires. Properly rated terminals also resist corrosion, maintaining reliable connections even in harsh environments. Corrosion can cause increased resistance, heat buildup, and eventual connection failure, so selecting terminals suited for your application is crucial. Skimping on ratings might save money initially but can result in costly repairs or safety hazards later. Always verify the current, voltage, and environmental conditions to choose connectors and terminals designed to handle your system’s demands, ensuring safe, long-lasting connections.

Recognizing and Preventing Overcurrent Events

Overcurrent events can occur suddenly and cause significant damage to your electrical system if not recognized and addressed promptly. Circuit overloads are common causes, risking overheating and fires. To prevent this, use surge protection devices and avoid connecting too many appliances on one circuit. Watch for signs like flickering lights or frequent breaker trips—they indicate an overload.

| Warning Signs | Potential Causes | Preventive Actions |

|---|---|---|

| Flickering lights | Circuit overloads | Limit appliances per circuit |

| Tripped breaker | Faulty wiring | Install surge protection |

| Burning smell | Overheating components | Regular system inspections |

| Warm outlets | Overcurrent stress | Avoid daisy-chaining devices |

Essential Safety Standards and Compliance Guidelines

Ensuring your electrical system adheres to safety standards and compliance guidelines is vital for preventing hazards and maintaining reliable operation. Proper grounding techniques are essential, as they reduce the risk of electrical shocks and equipment damage. Always follow established grounding methods to guarantee safety and system integrity. Battery safety is another key aspect; use the correct fuses and connectors designed for your battery type to prevent overcurrent situations and potential fires. Comply with local codes and standards, such as NEC or IEC regulations, to stay within legal requirements and promote safe practices. Regular inspections and maintenance help identify issues early, guaranteeing your system remains compliant. Staying informed about safety standards not only protects your equipment but also keeps you safe from electrical hazards.

Frequently Asked Questions

How Do Environmental Factors Affect Fuse and Connector Safety?

Environmental factors like moisture intrusion and corrosion effects directly impact fuse and connector safety. You should regularly inspect for signs of corrosion or moisture buildup, as these can cause poor connections, short circuits, or outages. Moisture can lead to oxidation, weakening metal contacts and increasing resistance. By maintaining a dry environment and addressing corrosion early, you guarantee reliable performance and reduce the risk of electrical failures.

Are There Industry Standards for Fuse and Connector Markings?

Think of fuse and connector markings as a map guiding your safety journey. Industry standards do exist, ensuring that markings follow strict guidelines for clarity and reliability. You need to prioritize industry compliance and marking consistency, so every component communicates its purpose clearly. This consistency helps prevent mishaps, making sure your electrical system stays safe and efficient. Following these standards is like having a reliable compass in the complex terrain of electrical safety.

What Are Common Signs of Faulty Fuse or Connector Connections?

You’ll notice faulty fuse or connector connections through visual inspection, looking for signs like discoloration, burn marks, or melting. Corrosion detection is also key—check for rust, greenish deposits, or buildup on terminals. These signs indicate poor connections, which can cause overheating or electrical failure. Regularly inspecting and maintaining your fuses and connectors helps prevent potential hazards and guarantees your system operates safely and reliably.

How Does Temperature Impact Fuse Performance and Safety?

Temperature considerably impacts fuse performance and safety. When temperatures rise, thermal degradation can weaken the fuse’s materials, making it less reliable. If it reaches its melting point, the fuse may blow prematurely or fail to protect your circuit properly. High heat can also cause the fuse to melt or deform, risking electrical fires or damage. To guarantee safety, keep fuses within recommended temperature ranges and avoid exposing them to excessive heat.

Can Improper Installation Lead to Electrical Fire Risks?

Improper installation can definitely lead to electrical fire risks. If you make installation errors, such as poor connections or incorrect fuse placement, you increase the fire hazard substantially. Always double-check your wiring and make sure components are installed correctly to prevent overheating or short circuits. By avoiding these mistakes, you reduce the risk of fires and keep your electrical system safe and reliable.

Conclusion

Remember, understanding fuse and connector safety isn’t just technical jargon — it’s your shield against chaos. Think of each component as a guardian, standing watch to protect your circuits. By debunking myths and applying proper practices, you create a fortress of safety. So, don’t let misconceptions be the cracks in your armor. Stay informed, stay vigilant, and let safety be the guiding light that keeps your electrical world secure and sound.