To master fuse and connector safety in a weekend, focus on understanding basic principles like wire gauge, fuse ratings, and how components work together to protect circuits. Learn proper installation techniques, such as turning off power, verifying ratings, and securing connections correctly. Practice inspecting and testing devices with a multimeter, and follow safety regulations and standards. Keep safety gear handy and stay vigilant about signs of wear. If you continue exploring, you’ll discover more essential tips to guarantee safety and reliability.

Key Takeaways

- Study the fundamentals of wire gauge, fuse ratings, and their roles in circuit safety.

- Review different fuse types, installation best practices, and common connection mistakes.

- Practice visual inspections and multimeter testing to identify faults and ensure proper wiring.

- Familiarize yourself with safety standards (UL, IEC, NEC) and proper maintenance procedures.

- Develop a safety checklist, educate yourself on risk prevention, and reinforce a safety-first mindset.

Understanding the Basics of Fuses and Connectors

Fuses and connectors are essential components that guarantee your electrical systems operate safely and reliably. Understanding wire gauge is vital because it determines how much current a wire can safely carry without overheating. Selecting the right wire gauge helps prevent electrical fires and equipment damage. Similarly, fuse ratings indicate the maximum current a fuse can handle before it blows, protecting your circuit from overloads. Using a fuse with an appropriate rating ensures it will trip when necessary without causing unnecessary interruptions. Both fuse ratings and wire gauge work together to maintain safety and efficiency. Proper knowledge of these basics helps you choose the right fuse and connector for your specific electrical setup, minimizing risks and ensuring your system functions smoothly. Additionally, being aware of vape juice shelf life and proper storage can prevent safety issues related to expired or spoiled products.

Recognizing Different Types of Fuses and Their Uses

Knowing the different types of fuses is essential to selecting the right one for your electrical needs. Fuse types vary based on their construction, response time, and application, all important for effective circuit protection. Cartridge fuses, for example, are common in automotive circuits, offering reliable overcurrent protection. Blade fuses are easy to install and are typical in household and automotive uses. Slow-blow fuses handle temporary current surges, making them suitable for sensitive equipment. Fast-acting fuses protect circuits from sudden faults. Recognizing these fuse types helps you match the fuse to your device’s requirements, ensuring safety and proper circuit protection. Using the correct fuse type prevents damage and reduces safety risks, making understanding these differences essential for safe electrical work. Vetted

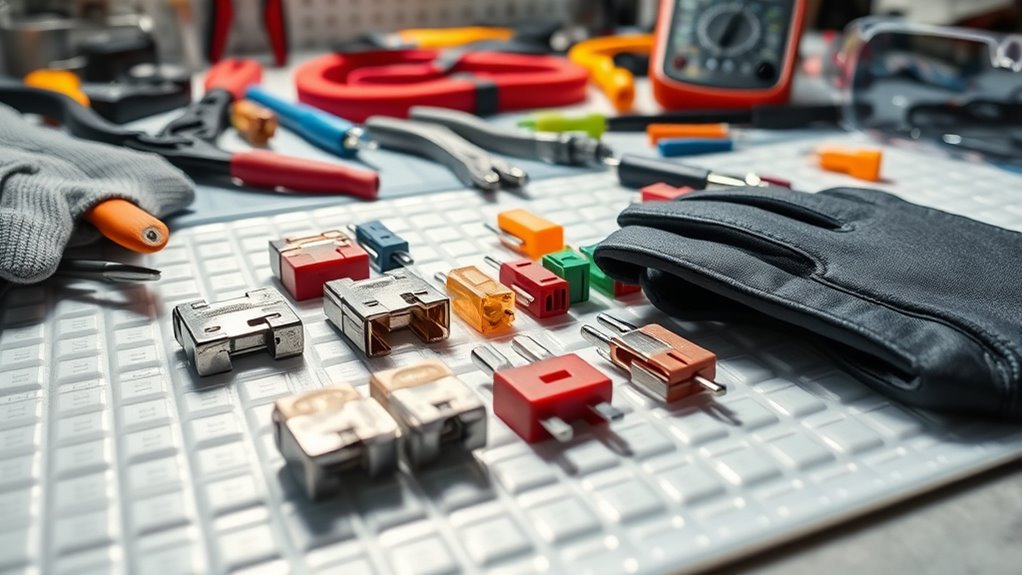

Essential Safety Gear and Precautions Before Handling

Before you start working on fuses or connectors, make sure you wear the right protective gear, like gloves and safety glasses. Always disconnect the power sources to prevent electrical shocks or short circuits. Taking these precautions helps keep you safe and avoids costly mistakes. Additionally, understanding the importance of proper electrical safety protocols can further reduce risks during maintenance.

Wear Protective Equipment

Wearing the right protective equipment is essential to guarantee your safety when handling fuses and connectors. Always don protective gloves to shield your skin from potential electrical sparks or contact with harmful substances. Safety glasses are equally important, protecting your eyes from debris or accidental sparks that could occur during installation or removal. Before working, ensure your gloves are in good condition, free of tears, and rated for electrical protection. Safety glasses should fit well and cover your eyes completely. Never skip this gear, even if you’re experienced; accidents happen quickly. Proper protective equipment minimizes risks and keeps you safe while working with electrical components. Remember, taking a few seconds to gear up can prevent serious injuries and ensure a safe, efficient process. Additionally, understanding the safety precautions associated with fuse and connector handling can further reduce the risk of hazards.

Disconnect Power Sources

Always guarantee that power sources are completely disconnected before working on fuses and connectors. This prevents electrical shock and equipment damage. Review circuit diagrams to identify all power connections, ensuring you don’t miss any sources. Check voltage ratings on components to confirm they match the power supply. Use insulated tools and wear protective gear for added safety. Before disconnecting, confirm the power is off by testing with a multimeter. Keep a table of device specifications handy:

| Device | Voltage Rating |

|---|---|

| Fuse Box | 120V / 240V |

| Connectors | 12V / 24V |

| Circuit Boards | 5V / 3.3V |

This helps you verify that you’re handling the correct voltage levels safely. Proper disconnection is essential for safe, effective maintenance. Additionally, understanding essential oils can help promote a calm and alert state during complex procedures.

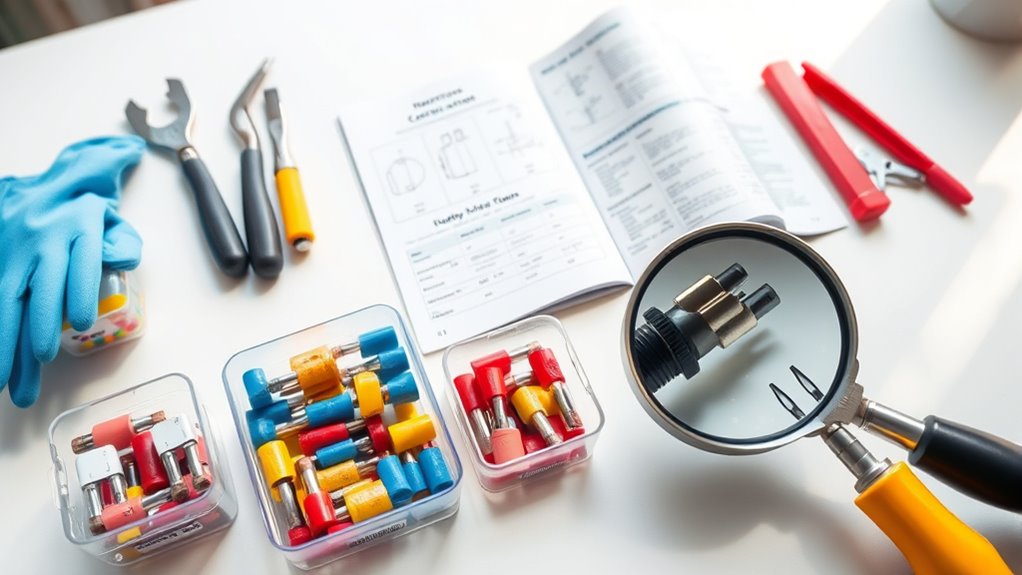

How to Properly Inspect and Test Fuses and Connectors

To guarantee your fuses and connectors are safe, start with a thorough visual inspection for signs of damage or corrosion. Then, use a multimeter correctly to test continuity and voltage, making sure the components function properly. Additionally, refer to best vacuum models and their filtration efficiency to understand which components are most critical for maintaining a safe and healthy environment. Finally, learn how to identify faulty parts quickly so you can replace them before they cause issues.

Visual Inspection Techniques

Properly inspecting fuses and connectors is essential to guarantee safety and reliable operation. Begin by referencing circuit diagrams to understand the correct connections and identify components quickly. Visually examine each fuse and connector for signs of damage, such as burns, cracks, or corrosion. Check safety labels for specific inspection instructions or warnings that may indicate potential hazards. Look for discoloration or melting, which signals overheating or failure. Ensure connectors are securely attached, with no loose or broken pins. Use a bright flashlight to spot small cracks or corrosion that might be missed in regular lighting. Combining these visual cues with circuit diagrams and safety labels helps you accurately assess the condition, preventing accidents and guaranteeing ideal performance. Regular maintenance of hydrotherapy equipment and systems also minimizes the risk of malfunctions during inspections.

Using Multimeter Effectively

Using a multimeter effectively is key to accurately testing fuses and connectors for continuity and proper function. First, familiarize yourself with circuit diagrams to identify test points quickly. Next, set your multimeter to the continuity or ohmmeter mode. When testing, pay attention to wire coloring to guarantee you’re probing the correct connections. Here’s how to proceed:

- Connect the probes to the fuse or connector, referencing circuit diagrams to locate the right terminals.

- Observe the multimeter reading; a steady beep or a near-zero ohm value indicates good continuity.

- For connectors, test each pin systematically, checking wire coloring to avoid confusion.

- Remember to verify the multimeter’s calibration before testing to ensure accurate readings.

This approach ensures precise diagnosis and safe, reliable testing of electrical components.

Identifying Faulty Components

When inspecting fuses and connectors for faults, you should start by visually examining each component for obvious signs of damage, such as burns, corrosion, or broken terminals. Check for discoloration or melting that indicates overheating. Use circuit diagrams to trace connections and verify proper wiring. Pay attention to wire gauge; if wires are undersized, they may cause overheating or failure. Test the fuse by removing it and checking for continuity with a multimeter—no continuity means it’s defective. For connectors, ensure pins are secure and free of corrosion or dirt. If a connector feels loose or shows corrosion, replace it. Properly identifying faulty components helps prevent future failures and ensures your system operates safely and efficiently. Additionally, assessing contrast ratio and color accuracy can help diagnose deeper issues with image quality, ensuring your home theater functions optimally.

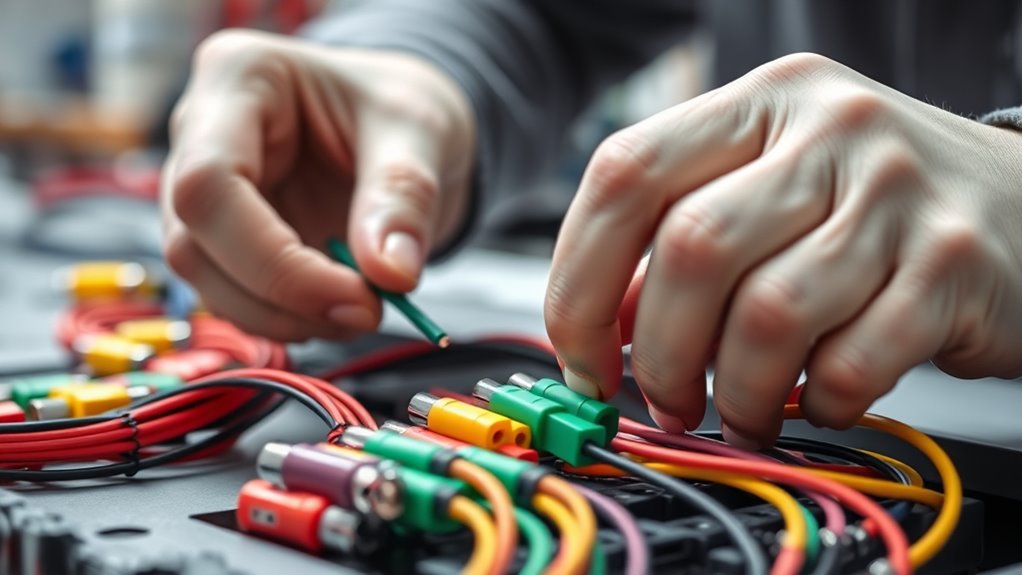

Step-by-Step Guide to Installing Fuses Safely

Installing fuses safely is vital to prevent damage and guarantee reliable operation of your electrical system. Follow these steps to ensure proper installation with an emphasis on electrical insulation and fire safety:

- Turn off the power supply before handling the fuse to avoid electrical shock.

- Check that the fuse’s amperage matches the circuit requirements and verify it’s properly insulated to prevent accidental contact.

- Insert the fuse securely into the fuse holder, making sure there’s no exposed metal that could compromise fire safety or electrical insulation.

- Be aware that using appropriate fuse ratings is essential for protecting your electrical components and maintaining system safety.

Common Mistakes to Avoid When Connecting Components

Connecting electrical components improperly can lead to serious safety hazards and system failures. One common mistake is choosing the wrong wire gauge, which can cause overheating or insufficient power flow. Always match the wire gauge to the component’s requirements to guarantee safety and proper operation. Another mistake is neglecting proper color coding; using incorrect or inconsistent colors can cause confusion and wiring errors. Stick to standard color codes for power, ground, and signal wires, and double-check connections before powering up. Additionally, avoid mixing wire sizes or ignoring manufacturer instructions. Properly securing connections and verifying polarity is essential. Taking these precautions helps prevent shorts, fires, and damage, keeping your system safe and functioning reliably.

Troubleshooting and Maintaining Fuse and Connector Systems

To keep your fuse and connector systems running smoothly, you need to know some key troubleshooting techniques and regular maintenance practices. By staying alert for signs of system failures, you can catch issues early and prevent costly damage. Let’s explore how to identify problems quickly and keep your system in top condition.

Common Troubleshooting Techniques

When troubleshooting fuse and connector systems, identifying the root cause of electrical issues is vital for effective maintenance. Start by examining the circuit diagram to understand how components are connected and locate potential problem areas. Next, check voltage regulation at key points to guarantee consistent power flow; fluctuations often point to faulty fuses or connectors. Finally, use a multimeter to test for continuity across connectors and fuses—this reveals open circuits or shorts. Always verify that the fuse ratings match specifications, and look for corrosion or damaged pins in connectors. These techniques help you systematically diagnose issues, saving time and preventing unnecessary replacements. Remember, proper troubleshooting is essential for safe, reliable operation of your fuse and connector systems.

Regular Maintenance Practices

Regular maintenance is essential to keep fuse and connector systems functioning reliably. Start by reviewing circuit diagrams regularly to guarantee connections remain correct and identify any signs of wear or corrosion. Check that fuses and connectors match the specified voltage ratings to prevent overloads or failures. Clean contacts with proper tools to remove dirt and oxidation that can cause poor connections. Inspect fuses for any signs of damage, such as cracks or discoloration, and replace them promptly. Always verify that replacements meet the original voltage ratings to maintain system safety. Document maintenance activities to track issues over time and anticipate future needs. Consistent checks help catch problems early, ensuring your system stays safe and efficient.

Identifying System Failures

How can you effectively identify system failures in fuse and connector systems? Start by inspecting for signs of circuit overloads, such as blown fuses or melted connectors. Next, check for corrosion, which can cause poor connections and intermittent failures. Lastly, listen for unusual noises or look for discoloration around connectors that indicate damage or overheating. To prevent future issues, ensure corrosion prevention measures are in place and that fuses are rated correctly to handle load demands. Regular visual inspections help catch early signs of failure before they cause more extensive damage. By staying vigilant and performing routine checks, you’ll quickly pinpoint issues and maintain a safe, reliable fuse and connector system.

Best Practices for Handling and Storage

Proper handling and storage of fuses and connectors are essential to guarantee safety and maintain their functionality. To do this, follow effective storage tips by keeping components in a dry, cool environment away from direct sunlight and moisture. Use designated containers or compartments to prevent damage and mix-ups. Labeling methods are vital—accurately mark storage containers with details such as fuse ratings, types, and installation dates. This helps you quickly identify the right part when needed and reduces the risk of errors. Handle components carefully to avoid bending or breaking connectors. Always store unused fuses and connectors separately from active systems to prevent accidental contact or short circuits. Good organization and clear labels keep your workspace safe and efficient.

Important Regulations and Standards to Know

Are you aware of the key regulations and standards that govern fuse and connector safety? Understanding these is vital for proper circuit protection and voltage regulation. Here are three essentials to keep in mind:

- UL Standards: These ensure your fuses and connectors meet safety requirements, minimizing risks and ensuring reliable circuit protection.

- IEC Regulations: International standards that govern electrical components, helping you maintain consistent safety practices across different environments.

- NEC Codes: Local electrical codes that specify safe wiring and fuse ratings, essential for proper voltage regulation and preventing overloads.

Knowing these standards helps you select the right components, avoid hazards, and guarantee your electrical systems are compliant and safe.

Resources for Continuing Your Safety Education

Staying updated on fuse and connector safety is essential, and numerous resources are available to support your ongoing education. Industry websites and safety organizations offer detailed guides on best practices, including safe handling of wireless charging devices and proper fuse recycling methods. Attending workshops or online courses can deepen your understanding, especially as technology evolves. Manufacturers often provide safety manuals and troubleshooting tips relevant to modern applications. Subscribing to trade magazines or newsletters keeps you informed about the latest innovations and safety standards. Remember, continuous learning helps you prevent accidents and maintain compliance. By leveraging these resources regularly, you’ll stay current on safety protocols and ensure that your work with fuses, connectors, and related technology remains safe and effective.

Frequently Asked Questions

How Often Should Fuse and Connector Safety Training Be Refreshed?

You should refresh fuse and connector safety training at least annually, aligning with your inspection protocols and maintenance schedules. Regular updates help you stay current on safety practices, identify new risks, and guarantee compliance. Incorporate refresher sessions into your routine maintenance plans so your team consistently follows best practices. Frequent training not only minimizes hazards but also keeps safety top of mind, reducing the likelihood of accidents and equipment damage.

What Are the Signs of a Failing Fuse or Connector?

You can spot a failing fuse or connector through visual inspection, looking for signs like discoloration, burns, or melting. Corrosion detection is essential—check for rust, greenish or white powdery deposits, which indicate deterioration. If you notice these signs, replace the fuse or connector promptly, as they can cause electrical failures or hazards. Regular inspections help prevent unexpected breakdowns and guarantee safety in your electrical system.

Can DIY Repairs Compromise Safety Standards?

Yes, DIY repairs can compromise safety standards if you’re not careful. DIY hazards include improper handling, incorrect wiring, or using incompatible parts, which can lead to electrical failures or fires. To guarantee safety compliance, you need to follow proper procedures, use the right tools, and understand fuse and connector specifications. Skipping professional guidance might save time but risks violating safety standards, potentially endangering you and others.

Are There Specific Safety Considerations for High-Voltage Systems?

Did you know high-voltage systems can be 1,000 volts or more? Safety is essential, so you must prioritize voltage insulation and thermal management. Always guarantee proper insulation to prevent accidental shocks, and manage heat effectively to avoid overheating. Use insulated tools and double-check connections. Staying vigilant with these safety considerations helps protect you from serious injury and keeps high-voltage systems operating safely.

How Do Environmental Factors Affect Fuse and Connector Safety?

Environmental factors, like moisture and temperature, directly impact fuse and connector safety. You should focus on corrosion prevention by keeping components dry and protected from humidity, which can cause rust and poor connections. Thermal stress from extreme temperatures can weaken the materials, so verify your system is rated for the environment. Regular inspections and proper sealing help maintain safety, preventing failures caused by environmental wear and tear.

Conclusion

By mastering fuse and connector safety over a weekend, you’ll protect yourself and your equipment. For example, imagine troubleshooting a faulty circuit—using proper inspection and safety gear prevents costly mistakes. Keep learning, stay cautious, and follow best practices. With this knowledge, you can confidently handle installations and repairs, ensuring safety and reliability. Remember, a little preparation goes a long way in avoiding accidents and keeping your projects running smoothly.