To accurately diagnose tilt and spacing issues, you need to understand key calculations like measuring angles with trigonometry, especially sine, cosine, and tangent functions. Use these to determine the true length and angle of tilted structures, as well as vertical and horizontal distances, often applying Pythagoras’ theorem. Correctly interpreting these results helps guarantee stability, safety, and compliance. Keep going, and you’ll learn how to perform these essential calculations confidently.

Key Takeaways

- Use trigonometric functions like sine, cosine, and tangent to accurately calculate tilt angles and component lengths.

- Regularly calibrate measurement tools such as inclinometers and laser levels to ensure precise tilt and spacing assessments.

- Apply the Pythagorean theorem to determine true lengths of inclined beams and verify structural stability.

- Measure and adjust for material expansion and tilt deviations to maintain uniform spacing and safety standards.

- Continuously monitor structural shifts and foundation settlement to detect and correct tilt-related issues early.

Understanding the Basics of Tilt Measurement

To accurately assess tilt, you need to understand the fundamental concepts behind measurement techniques. Materials testing plays a crucial role in guaranteeing the accuracy of tilt measurements, as it helps verify the reliability of tools and methods used. Proper project management ensures that measurement procedures are consistent and documented, minimizing errors. When measuring tilt, you focus on detecting deviations from a true vertical or horizontal plane, which affects structural integrity and safety. Knowing the basics of measurement techniques, such as using levels or inclinometers, helps you obtain precise data. This foundation enables you to interpret results correctly and plan necessary adjustments. Effective project management ensures the measurement process stays on track, accuracy is maintained, and the data collected supports reliable decision-making. Additionally, understanding the potential vulnerabilities of measurement tools, similar to AI safety concerns, can help in developing robust calibration protocols to improve overall measurement trustworthiness.

Calculating Tilt Angles Using Trigonometry

When calculating tilt angles, applying trigonometry provides a straightforward and accurate method for determining the degree of deviation from vertical or horizontal planes. You’ll use simple trigonometric functions to find the angle measurement directly from your measurements. Here’s how to approach it:

- Identify the opposite and adjacent sides of the tilt triangle.

- Use functions like sine, cosine, or tangent to calculate the angle.

- Use a calculator to find the inverse trigonometric function that corresponds to your ratio.

- Understanding the trigonometric functions involved allows for precise measurements in various engineering and construction applications.

Determining Vertical and Horizontal Spacing

After calculating tilt angles, measuring vertical and horizontal spacing becomes straightforward. You’ll want to prioritize aesthetic considerations to guarantee the overall design remains balanced and visually appealing. Proper spacing enhances structural integrity and creates harmony between elements. To determine vertical spacing, measure the distance between the top and bottom points, considering the tilt to avoid miscalculations. For horizontal spacing, assess the distance between side-by-side components, adjusting for tilt to maintain uniformity. Your material selection influences these measurements, as different materials respond differently to tilt and spacing. Use precise tools and double-check measurements to guarantee accuracy. Correct spacing not only improves the structure’s appearance but also optimizes its stability and function. Understanding cybersecurity vulnerabilities can help prevent disruptions that may impact your design projects. Accurate calculations are essential for achieving a cohesive, well-balanced design.

Applying Pythagoras’ Theorem in Structural Analysis

Applying Pythagoras’ Theorem is a powerful method for analyzing structures with tilted or uneven components. It helps you calculate unknown lengths and angles, which are vital for proper materials selection and understanding load distribution. By applying this theorem, you can determine the true length of inclined beams or supports, ensuring your design withstands forces accurately. Understanding local laws can influence how you approach structural analysis and compliance.

Using Pythagoras’ Theorem accurately measures inclined structures for safer, more efficient designs.

- Visualize how tilt impacts load paths and material stresses

- Calculate precise measurements to optimize materials and reduce waste

- Assess the stability of inclined structures for safer, more reliable designs

Using Pythagoras’ Theorem allows you to make informed decisions about material strength, placement, and how forces are distributed across your structure. It’s an essential tool for ensuring your design’s safety and efficiency.

Using Inclination Data to Ensure Structural Stability

Using inclination data allows you to directly assess how tilted components affect a structure’s stability. When you analyze tilt measurements, you can identify areas where tilt correction is needed to prevent further deterioration or failure. Proper tilt correction ensures that load distribution remains balanced, enhancing foundation stability. By evaluating inclination angles, you can determine whether structural elements are shifting or settling unevenly. This data helps you prioritize repairs, reinforcing the foundation where necessary. Accurate inclination readings also enable you to predict potential risks, such as structural cracks or uneven settling, allowing proactive interventions. Incorporating inclination monitoring into your assessment process helps maintain the integrity of the entire structure and ensures long-term stability.

Measuring and Adjusting for Accurate Spacing in Construction

To guarantee accurate spacing in construction, you need reliable measurement techniques and properly calibrated tools. Using real-time adjustment strategies helps you respond quickly to any discrepancies. Mastering these methods guarantees your project stays precise and on track. Regularly verifying the measurement accuracy of your tools can prevent costly errors and ensure consistent results.

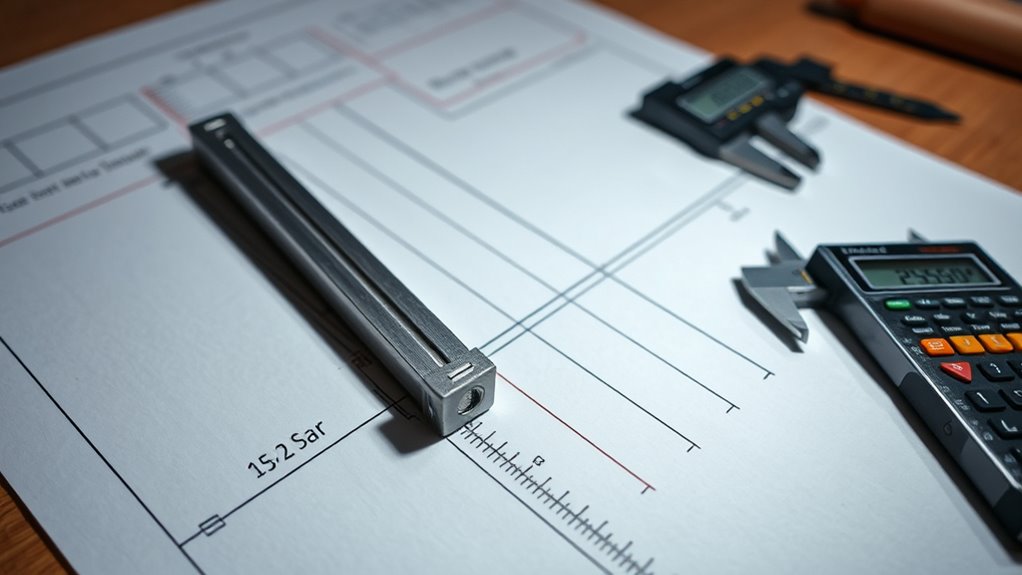

Precise Measurement Techniques

Achieving accurate spacing in construction relies on precise measurement techniques that guarantee each component fits correctly. Understanding material properties helps you select the right tools and methods, ensuring measurements account for expansion, contraction, or deformation. Historical case studies reveal how overlooked measurement precision caused failures, emphasizing the importance of meticulous techniques. To improve accuracy, consider these key practices:

- Use laser levels and digital calipers for high precision.

- Cross-verify measurements with multiple tools.

- Document measurements carefully for future reference.

- Being aware of material behavior ensures measurements remain accurate under various environmental conditions.

Calibration of Tools

Proper calibration of measurement tools guarantees that your spacing is accurate and reliable. Regular tool calibration guarantees that your measurements are precise, reducing the risk of errors that can compromise your project. To calibrate your tools effectively, follow manufacturer instructions and verify measurements with a known standard or reference. This process helps you identify and correct deviations, maintaining measurement integrity. Accurate calibration minimizes error, which is vital in construction where even small inaccuracies can lead to significant misalignments. Keep calibration tools, such as spirit levels, laser devices, and tape measures, in good condition and recalibrate periodically. Additionally, understanding the importance of a well-designed Bedroom space can influence how you approach measurements and adjustments in your work. By prioritizing tool calibration, you enhance measurement accuracy, streamline your workflow, and achieve consistent, professional results in spacing and alignment.

Real-time Adjustment Strategies

In construction, making real-time adjustments is essential for maintaining accurate spacing as work progresses. When you encounter tilt or material expansion, quick measures are crucial to keep everything aligned. To achieve this, you can implement effective strategies like tilt correction, adjusting for material expansion, and monitoring shifts regularly. Additionally, utilizing expert voice actors can help convey technical instructions clearly in training videos for construction teams. Use laser levels for instant tilt correction to prevent misalignment. Incorporate temperature checks to anticipate and compensate for material expansion. Regularly verify measurements with calibrated tools to catch deviations early. These tactics ensure your spacing remains precise and consistent. By addressing tilt correction promptly and accounting for material expansion, you avoid costly rework and maintain structural integrity. Staying vigilant and adaptable during construction allows you to uphold quality and efficiency without sacrificing safety.

Interpreting Results for Safety and Compliance

Interpreting the results of tilt and spacing diagnostics is essential to guaranteeing safety and compliance. If the data indicates significant foundation settlement, it signals potential risks of structural instability, requiring immediate attention. Look for patterns suggesting uneven shifts, which may point to material fatigue weakening the structure over time. Consistent deviations beyond acceptable thresholds could violate safety standards, risking damage or failure. By accurately analyzing these results, you can determine whether corrective measures are necessary. Recognizing signs of foundation movement or material fatigue early helps prevent costly repairs and ensures compliance with building codes. Additionally, understanding how automation in business enhances efficiency can assist in streamlining maintenance and monitoring processes. Ultimately, clear interpretation guides your decisions, maintaining the safety of occupants and the longevity of the structure.

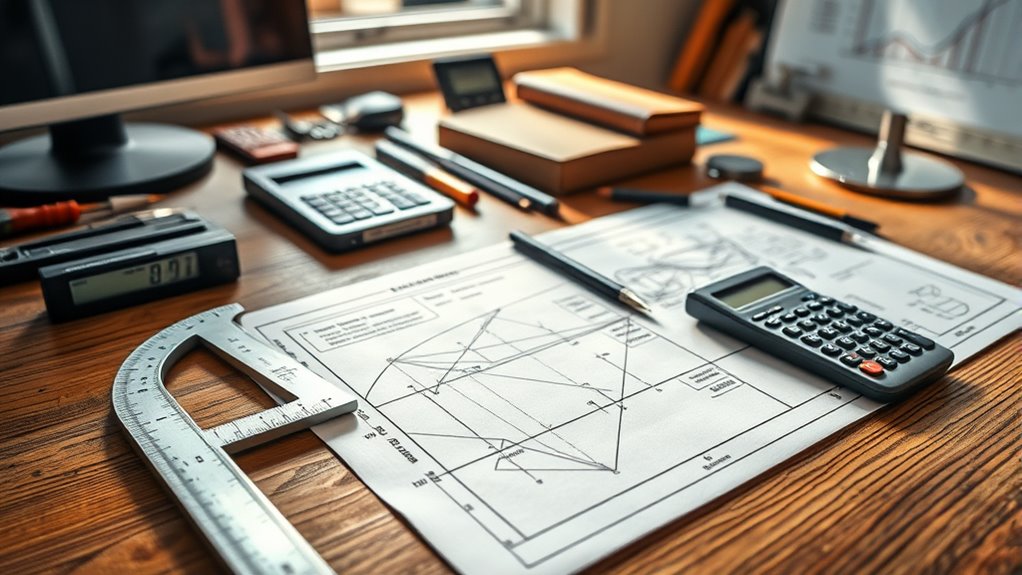

Tools and Techniques for Precise Tilt and Spacing Calculations

Accurate tilt and spacing calculations rely on a combination of advanced tools and precise techniques. To achieve ideal tilt correction and spacing optimization, you need reliable instruments and methods. Digital inclinometers and laser measurement devices provide high accuracy, making it easier to measure tilt angles precisely. Software programs offer detailed analysis and help visualize adjustments clearly. Additionally, applying geometric principles and calibration techniques ensures consistent results. These tools and techniques streamline the process, minimize errors, and ensure your calculations are dependable.

- Use laser measurement tools for precise tilt correction and spacing analysis

- Leverage specialized software for detailed modeling and adjustments

- Incorporate calibration methods to enhance accuracy and consistency

Frequently Asked Questions

How Do Environmental Factors Affect Tilt and Spacing Measurements?

Environmental factors like soil variability and temperature impacts substantially influence tilt and spacing measurements. Soil variability causes uneven settling, leading to inaccurate measurements if not accounted for. Temperature fluctuations affect material expansion or contraction, altering tilt and spacing readings over time. You need to monitor these environmental conditions regularly to guarantee precise measurements, adjusting your calculations accordingly. Ignoring these factors can lead to errors and compromise the integrity of your assessment.

What Are Common Mistakes to Avoid During Calculations?

You should avoid measurement errors and calculation pitfalls during your calculations. Double-check your measurements for accuracy, as small errors can lead to significant mistakes. Be cautious with units and conversions, ensuring consistency throughout. Don’t rush the process—careful step-by-step calculations prevent common pitfalls. Keep your tools calibrated and verify results at each stage. By staying attentive, you minimize errors and ensure precise tilt and spacing measurements.

How Often Should Tilt and Spacing Be Re-Evaluated in Structures?

You should re-evaluate tilt stability and spacing measurements regularly, typically every 6 to 12 months, depending on the structure’s age, load, and environmental conditions. Frequent measurement intervals ensure early detection of shifts or instability. If you notice any signs of movement or unusual tilting, it’s vital to perform assessments immediately. Consistent re-evaluation helps maintain safety and allows timely intervention before serious issues develop.

Can Digital Tools Replace Manual Calculations for Accuracy?

Sure, digital tools can seem like magic, making manual calculations feel obsolete. But don’t forget, they’re only as good as your input. While digital tools often boost accuracy, they can’t fully replace manual calculations for critical tilt and spacing diagnosis. You still need a solid understanding and careful verification, because relying solely on technology might overlook subtle errors that manual calculations catch. Balance both for the best results.

What Safety Protocols Are Essential During Measurement and Adjustment?

You need to wear protective gear, like gloves and goggles, to stay safe during measurement and adjustment. Always follow emergency procedures in case of accidents or equipment failure. Make certain your workspace is clear, and double-check your tools before starting. Communicate clearly with team members, and be prepared to shut down equipment quickly if something goes wrong. Staying alert and following safety protocols keeps you safe and ensures accurate results.

Conclusion

Mastering tilt and spacing calculations is your secret weapon for flawless structures that could withstand a hurricane’s fury. By understanding the basics, applying the right formulas, and using precise tools, you guarantee safety and compliance at every step. Skipping these calculations isn’t an option—you risk structural chaos. Stay diligent, trust your measurements, and turn complex data into rock-solid stability. Your expertise can transform construction into an unstoppable force of engineering excellence!